Change crankshaft position sensor

#1

Retired Senior Admin

Expert Gearhead

Thread Starter

Join Date: May 2006

Location: Sheboygan Wisconsin

Posts: 29,661

Likes: 0

Received 28 Likes

on

24 Posts

Jack up the passenger side of your car and put a jack stand in place. Never work under or around your car without a jack stand in place!

Before getting started, you will need a new crank bolt. Do not reuse the old one. INTENSE-Racing.com: Crank Bolt

Disconnect the negtive battery cable

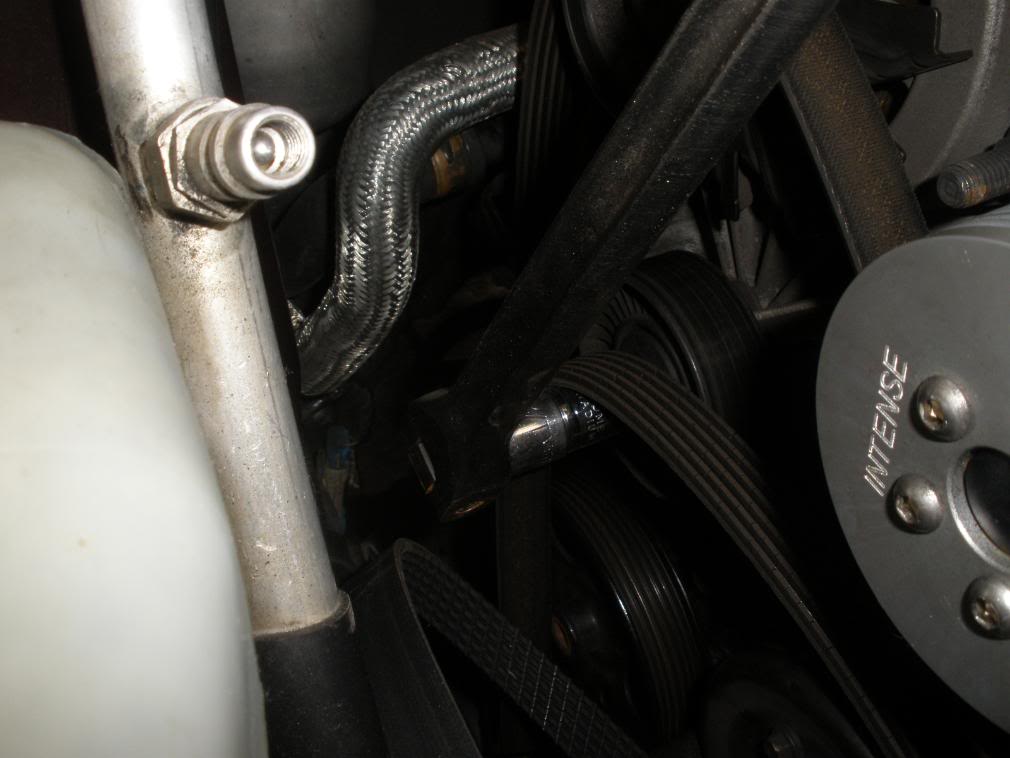

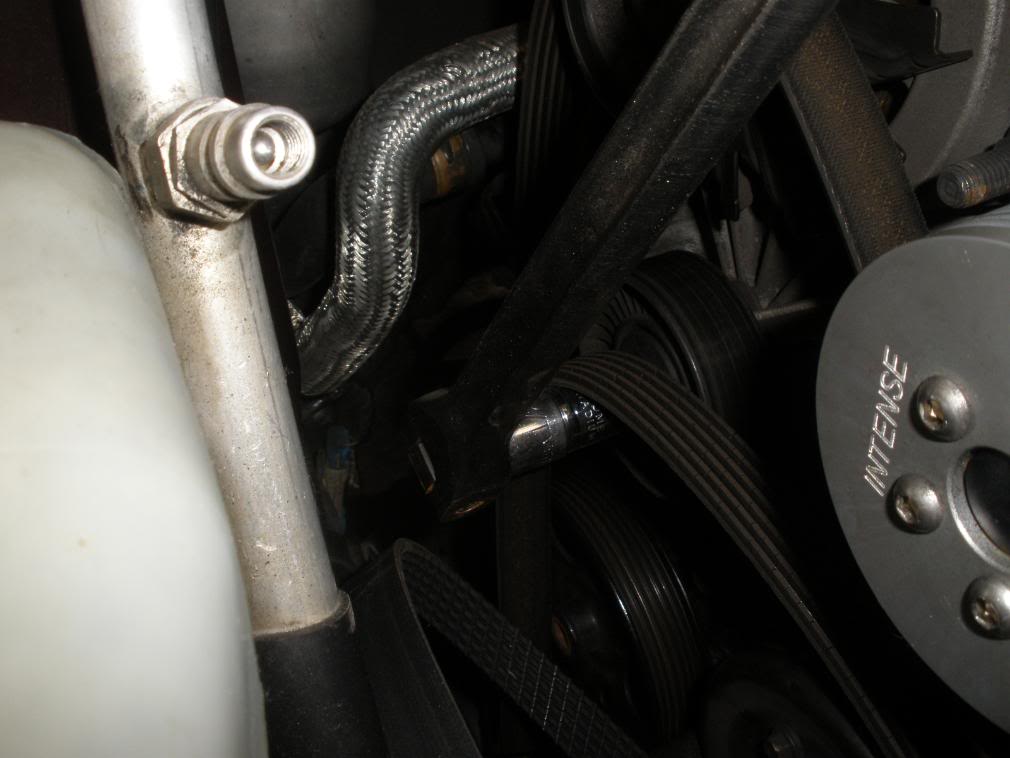

You will need to remove the serpentine belt. If engine has a supercharger installed, you will also need to remove the supercharger belt.

Now remove the wheel and splash guard

You will need a Harmonic Balancer Puller, you can get these are any auto parts store.

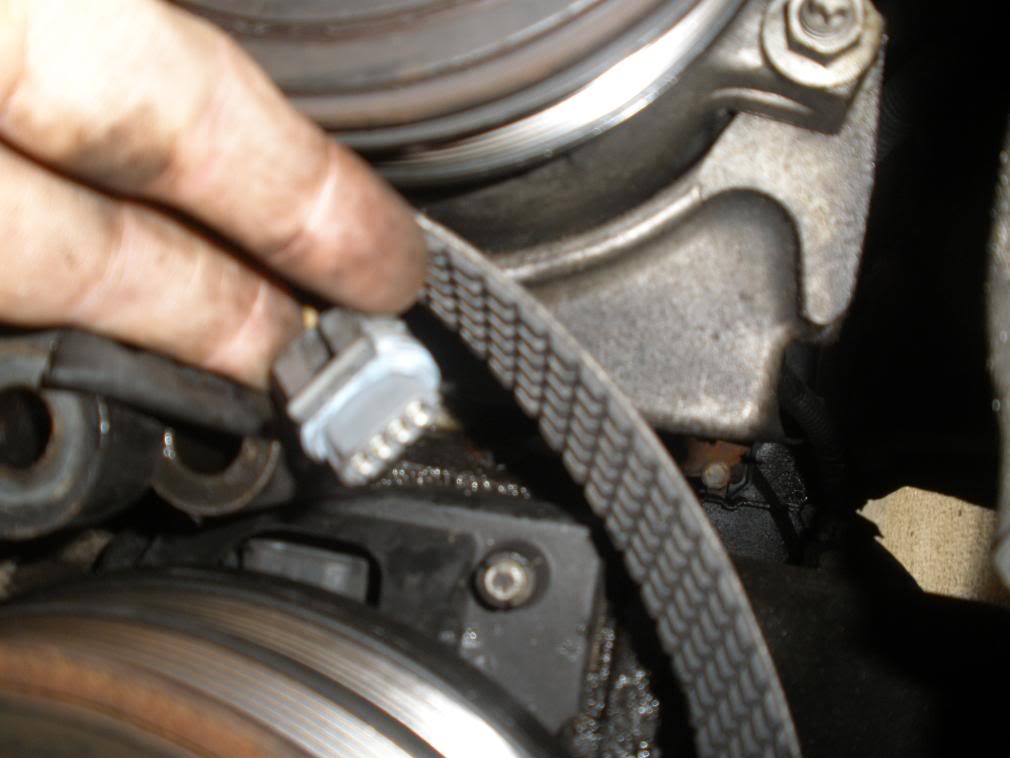

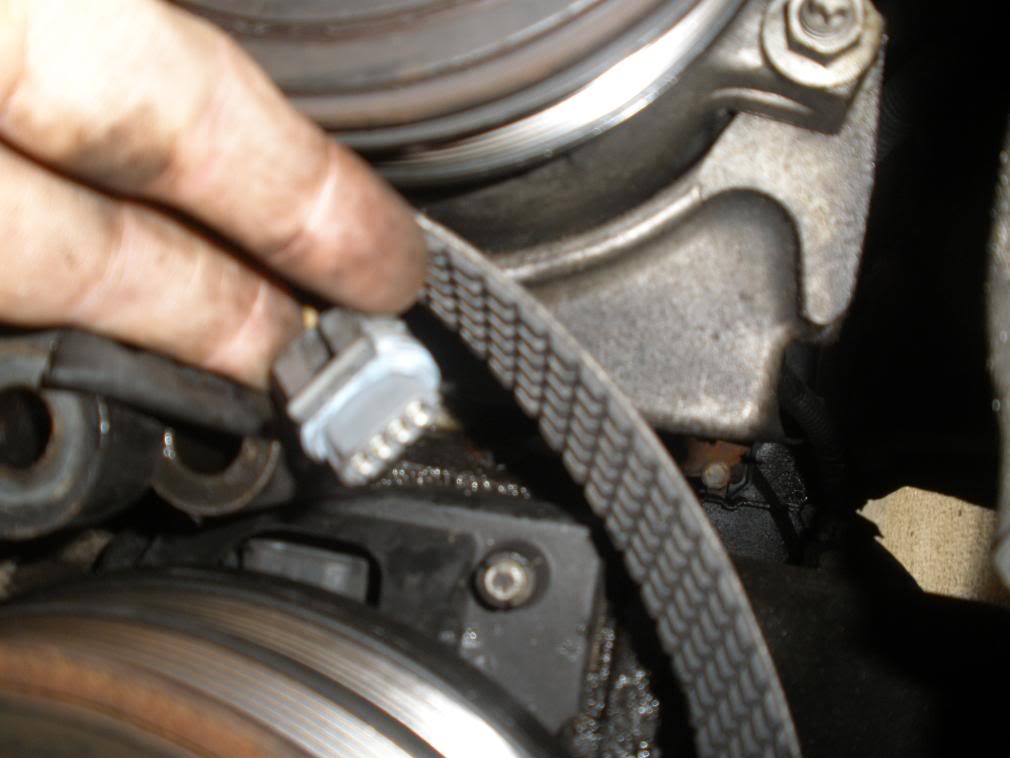

Unplug the crank shaft position sensor.

Remove two plastic flywheel covers with a 10mm socket. Twist and pull the front plastic piece to remove.

Now use a heavy screwdriver and push it through closest hole in flex plate to the front bottom edge of engine block. This will hold the flywheel in place so you can remove the crank bolt.

Use a 28mm 6 point socket on the crank pulley bolt and attach a breaker bar. Turn the engine counter clockwise until the screwdriver jams against engine this will hold the crankshaft in place.

You will most likely need a cheater bar over the handle to break the bolt free. Use a jack stand to hold the extension for your breaker bar so you can really apply force. It'* going to take a LOT. You may need to add a pipe extension to your breaker bar.

Safety warning!!

Use only high quality 6 point impact socket with 1/2" or larger drive. make sure the area is clear and when doing this position yourself that if the bolt breaks loose suddenly, or any part of the tool fails, you will not get hurt.

Now use your Harmonic Balancer Puller to remove the pulley.

No not separate the balancer from the pulley. Keep this together as a unit.

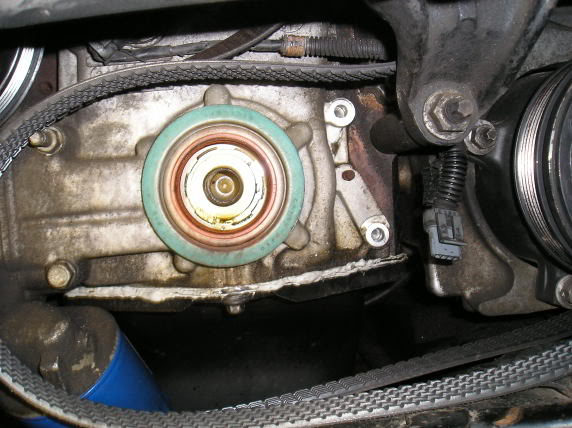

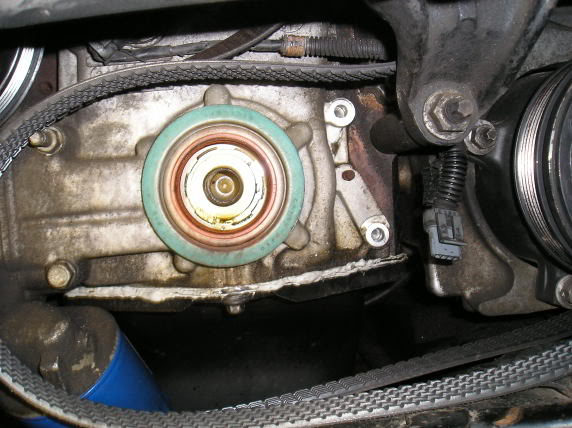

It should now look something like this.

Now remove the plastic crankshaft position sensor shield and old sensor. (Do not use a pry bar)

Clean everything up real good

Now take your sensor.

Install the sensor until the spacer lightly touches the sensor ring, and tighten the sensor mounting bolt 14-28 ft lbs

Now replace the plastic crankshaft position sensor shield.

Make sure all parts are in place

And put balancer back on the crankshaft. Be sure to use the proper tools to do this as pounding the balancer on the crankshaft can cause damage. Be sure to torque to the proper specification.

https://www.gmforum.com/t278801/

https://www.gmforum.com/t278799/

Plug the sensor wire back in to the sensor.

Put the splash guard and wheel back in place. Be sure to torque lug nuts to the proper setting. (100 ft lbs)

Remove the jack stand and lower car back down.

Install the serpentine belt.

Connect the negative battery cable.

Before getting started, you will need a new crank bolt. Do not reuse the old one. INTENSE-Racing.com: Crank Bolt

Disconnect the negtive battery cable

You will need to remove the serpentine belt. If engine has a supercharger installed, you will also need to remove the supercharger belt.

Now remove the wheel and splash guard

You will need a Harmonic Balancer Puller, you can get these are any auto parts store.

Unplug the crank shaft position sensor.

Remove two plastic flywheel covers with a 10mm socket. Twist and pull the front plastic piece to remove.

Now use a heavy screwdriver and push it through closest hole in flex plate to the front bottom edge of engine block. This will hold the flywheel in place so you can remove the crank bolt.

Use a 28mm 6 point socket on the crank pulley bolt and attach a breaker bar. Turn the engine counter clockwise until the screwdriver jams against engine this will hold the crankshaft in place.

You will most likely need a cheater bar over the handle to break the bolt free. Use a jack stand to hold the extension for your breaker bar so you can really apply force. It'* going to take a LOT. You may need to add a pipe extension to your breaker bar.

Safety warning!!

Use only high quality 6 point impact socket with 1/2" or larger drive. make sure the area is clear and when doing this position yourself that if the bolt breaks loose suddenly, or any part of the tool fails, you will not get hurt.

Now use your Harmonic Balancer Puller to remove the pulley.

No not separate the balancer from the pulley. Keep this together as a unit.

It should now look something like this.

Now remove the plastic crankshaft position sensor shield and old sensor. (Do not use a pry bar)

Clean everything up real good

Now take your sensor.

Install the sensor until the spacer lightly touches the sensor ring, and tighten the sensor mounting bolt 14-28 ft lbs

Now replace the plastic crankshaft position sensor shield.

Make sure all parts are in place

And put balancer back on the crankshaft. Be sure to use the proper tools to do this as pounding the balancer on the crankshaft can cause damage. Be sure to torque to the proper specification.

https://www.gmforum.com/t278801/

https://www.gmforum.com/t278799/

Plug the sensor wire back in to the sensor.

Put the splash guard and wheel back in place. Be sure to torque lug nuts to the proper setting. (100 ft lbs)

Remove the jack stand and lower car back down.

Install the serpentine belt.

Connect the negative battery cable.

Thread

Thread Starter

Forum

Replies

Last Post

princegohan01988

1987-1991

29

10-29-2007 10:00 PM