My L36 LIM Porting (with pics)...NOW WITH DATA!

#42

Senior Member

Posts like a Corvette

Thread Starter

Join Date: Jan 2007

Location: San Diego, CA

Posts: 1,451

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by willwren

A sharpie and a gasket are the worst thing you can possibly do.

While it'* certainly fair to say that I'm not using the best possible method, I'm thinking that, say, blindfolding myself and porting the LIM with a chainsaw might be worse than what I'm doing...

Originally Posted by karldergrosse

Agra- You laid the gasket down and traced with a sharpie and stayed away a 1/16th or so, so as not to create a "shelf" at the head. I laid down my aluminum gaskets on the morad LIM but it seemed there was a little to much room to move it around and still have everything lined up. I'm leaning towards this sharpie method as I can't afford the down time. So what is the best way to line up the gasket and be happy about making the trace?

#43

Junior Member

Posts like a Ricer Type-R

Ag, looking at your pic above, your ports are almost the same size as the gasket opening. If that is the case, you are almost certainly over-ported.

The idea here is to port match to the EXACT shape and size of the head port, including matching the radius on the inside corners. Obviously the tumor on the L36 port for the injector prevents a perfect rectangle, but all other corners should look just like the cylinder head intake port.

The reference is the centroid of each port. You may have to measure. Then go to the wrecker and measure edge-edge and center-center on an L36 that has the LIM off.

You don't want to introduce a variable like manufacturing tolerances of gaskets into this equation. After all, the whole idea is to get the MOST you can out of the LIM, right? Measure twice, cut. Measure again, cut. Repeat. Do all 3 ports on one side together, rough-in only. Then flip it around and do the same on the other side. Compare that to your measurements. Compare, measure, cut, over and over.

The idea here is to port match to the EXACT shape and size of the head port, including matching the radius on the inside corners. Obviously the tumor on the L36 port for the injector prevents a perfect rectangle, but all other corners should look just like the cylinder head intake port.

The reference is the centroid of each port. You may have to measure. Then go to the wrecker and measure edge-edge and center-center on an L36 that has the LIM off.

You don't want to introduce a variable like manufacturing tolerances of gaskets into this equation. After all, the whole idea is to get the MOST you can out of the LIM, right? Measure twice, cut. Measure again, cut. Repeat. Do all 3 ports on one side together, rough-in only. Then flip it around and do the same on the other side. Compare that to your measurements. Compare, measure, cut, over and over.

#44

Member

Posts like a V-Tak

Join Date: Mar 2007

Location: Alabama

Posts: 43

Likes: 0

Received 0 Likes

on

0 Posts

silly question, why not lay some masking tape over the head ports press on the tape to leave an impression of the bore on the tape... then peel the tape off, put it over the LIM port and cut out along the impression, remove the tape covering the port, then use a sharpie to mark where the head ports are so everything lines up right?

Edit, maybe double sided tape would work best so you don't have to flip the tape over.

Edit, maybe double sided tape would work best so you don't have to flip the tape over.

#45

Senior Member

Posts like a 4 Banger

Join Date: Mar 2007

Location: Brookfield WI

Posts: 121

Likes: 0

Received 0 Likes

on

0 Posts

Will,

If you are using the centroid of the port as a ref. point, then I assume you are taking off equal amounts on each side of the port. Is that a correct statement? Let'* say my measurement was 1.800 for top to bottom. Assuming the finished dimension should be 1.900, you then would grind .050 off the top of the port and .050 off the bottom of the port(obviously staying clear of inj. port). Correct? I know I am asking alot of questions but like you said, I don't want to scrap out an LIM. Thanks for your patience.

If you are using the centroid of the port as a ref. point, then I assume you are taking off equal amounts on each side of the port. Is that a correct statement? Let'* say my measurement was 1.800 for top to bottom. Assuming the finished dimension should be 1.900, you then would grind .050 off the top of the port and .050 off the bottom of the port(obviously staying clear of inj. port). Correct? I know I am asking alot of questions but like you said, I don't want to scrap out an LIM. Thanks for your patience.

#46

Junior Member

Posts like a Ricer Type-R

At the center of each side, the port is actually really close to the right dimension. It narrows as it approaches each corner, taking the short way around. Make sense? Keep in mind I had the luxury of having an L36 in my driveway torn down recently, and took advantage of it for careful measurements, like I did on the Zilla a couple years ago when I did that first LIM.

So you'll find the WIDEST and TALLEST points are already close, and you're turning that ugly port into a rectangle with the same matching sharper corners to match the heads.

I'm only trying to keep people away from the gaskets because:

1. They may vary by manufacturer (and there are several)

2. They may vary from lot to lot.

3. They're not a good SIZE reference to begin with.

4. They are essentially invisible to the airflow anyway.

You may not have the advantage of having exposed heads for measurement and fitting like I did, but at the same time, don't expect all LIM'* to be the same either. EK98'* LIM (which I measured, but didn't port) was identical in dimensions and flaws in the casting as the one I did for jr's3800. And Mike1995'* as well. This does NOT mean they all are.

Standard disclaimer. It'* worked for two installed so far. Both were 95'*. Casting numbers are not known. Lash will be doing one soon too, I think.

So you'll find the WIDEST and TALLEST points are already close, and you're turning that ugly port into a rectangle with the same matching sharper corners to match the heads.

I'm only trying to keep people away from the gaskets because:

1. They may vary by manufacturer (and there are several)

2. They may vary from lot to lot.

3. They're not a good SIZE reference to begin with.

4. They are essentially invisible to the airflow anyway.

You may not have the advantage of having exposed heads for measurement and fitting like I did, but at the same time, don't expect all LIM'* to be the same either. EK98'* LIM (which I measured, but didn't port) was identical in dimensions and flaws in the casting as the one I did for jr's3800. And Mike1995'* as well. This does NOT mean they all are.

Standard disclaimer. It'* worked for two installed so far. Both were 95'*. Casting numbers are not known. Lash will be doing one soon too, I think.

#47

Junior Member

Posts like a Ricer Type-R

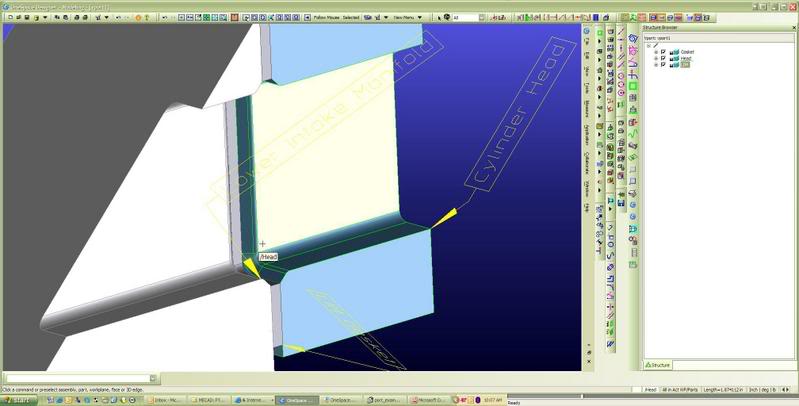

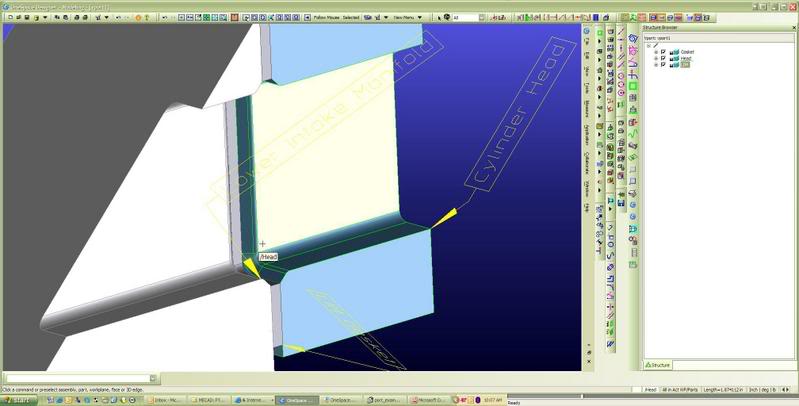

Here'* an idea I was going to pursue at one point, until I learned that it actually HURT flow. You want no 'interruption' at all. You're jumping the gasket gap from port to port. The problem is that you can't count on the gasket being perfectly place during assembly.

Just something to share, not to encourage anyone to do:

Just something to share, not to encourage anyone to do:

#48

Senior Member

Posts like a 4 Banger

Join Date: Mar 2007

Location: Brookfield WI

Posts: 121

Likes: 0

Received 0 Likes

on

0 Posts

Will,

I have to agree with you on trying to use gaskets. I hope Ag'* works for him but after trying to line my gasket up I said no way in h***. Way to much play that way and lining it up is just guessing. Are you confident in your dimensions of the head ports being .9 x 1.9? You mentioned you checked 3 different ones.

I have to agree with you on trying to use gaskets. I hope Ag'* works for him but after trying to line my gasket up I said no way in h***. Way to much play that way and lining it up is just guessing. Are you confident in your dimensions of the head ports being .9 x 1.9? You mentioned you checked 3 different ones.

#49

Junior Member

Posts like a Ricer Type-R

I measured a 93 L27, 93 L67 (twice), and a 98 L36. Mike1995 measured his 95 L36. All of them are the same port size.

Now would be a good time to ask others who may be torn down that far to measure more if it would boost your confidence. I ported jr's3800'* based on these measurements, and if you read the "ZillaMotorsports strikes again" topic here, you'll see that all his ports lined up and matched very well.

Now would be a good time to ask others who may be torn down that far to measure more if it would boost your confidence. I ported jr's3800'* based on these measurements, and if you read the "ZillaMotorsports strikes again" topic here, you'll see that all his ports lined up and matched very well.

#50

Senior Member

Posts like a 4 Banger

Join Date: Mar 2007

Location: Brookfield WI

Posts: 121

Likes: 0

Received 0 Likes

on

0 Posts

Those dimensions were for the ports on the heads, not the LIM. Yeah I just checked my LIM ports with my dial calipers. Only ned to take .005 off top and bottom (then obviously square it up to the corners), and about .015 off the sides then bringing that up and down to get her square(rectangular). Is the diameter of the rounded carbide dremel bit a good radius for the corners or do I need something smaller?