4T80E/Turbo-S/C... TIME FOR A NEW THREAD?

#141

Senior Member

Posts like a Turbo

Thread Starter

Join Date: Jan 2005

Location: Atlanta, GA. USA

Posts: 368

Likes: 0

Received 0 Likes

on

0 Posts

There is one turbo car I know of that is making close to 500whp on a bone-stock bottom end with onyl ARP bolts and studs to keep things togehter.

It'* all in the tune! The internal parts should not break unless they are STRESSED and if the tune is right, they will not be stressed beyond their inherent strength. GM uses a 2-2.5:1 margin of safety on mist things. The stock motor is rated at 240, so the rods should be good for 480-600. ZZP claimed a stock used block, no fancy fasteners even, in their 9-sec car about two years ago. Going off their claimed race weight, their trap speeds indicated over 600hp at the crank.

My goal is 500whp, which is about 600 at the crank.

It'* all in the tune! The internal parts should not break unless they are STRESSED and if the tune is right, they will not be stressed beyond their inherent strength. GM uses a 2-2.5:1 margin of safety on mist things. The stock motor is rated at 240, so the rods should be good for 480-600. ZZP claimed a stock used block, no fancy fasteners even, in their 9-sec car about two years ago. Going off their claimed race weight, their trap speeds indicated over 600hp at the crank.

My goal is 500whp, which is about 600 at the crank.

#142

Retired Moderator

True Car Nut

Join Date: Sep 2006

Location: Northwest Indiana

Posts: 3,047

Likes: 0

Received 0 Likes

on

0 Posts

#143

Senior Member

Posts like a Turbo

Thread Starter

Join Date: Jan 2005

Location: Atlanta, GA. USA

Posts: 368

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Pearl_bonnie02

The .96 a/r turbine hsg is in, I got the injectors. Now all I need is an 8-rib balancer and fuel rails. I still have alot of work to do at the shop, but I really need ot get it done soon. Maybe this weekend I can get the intercooler finished.

#144

PopaDopaDo

True Car Nut

My goal is 500whp, which is about 600 at the crank.

I thought the 4t80e had 24% loss; that translates to ~650 crank HP if you get ~500 at the tires.

#145

Senior Member

Posts like a Turbo

Thread Starter

Join Date: Jan 2005

Location: Atlanta, GA. USA

Posts: 368

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by popatim

My goal is 500whp, which is about 600 at the crank.

I thought the 4t80e had 24% loss; that translates to ~650 crank HP if you get ~500 at the tires.

I don't buy into the percent losses. At stock hp levels it'* extrapolated by taking the output at the wheels of a stock engine and doing the math to come up with something close to the factory hp rating. It doesn't work when you start making alot of hp. It takes the same amount of hp to turn a 4T80E, regardless of the input power. Same for any transmission, auto or manual. It takes the same amount of hp to turn the axles, spin the hubs, rotate the wheels, across a general speed range regardless of the input power. Where things get more inefficient is at speeds over 100mph. When all that mass of axles, bearings, wheels, is turning at that speed, power loss percentages climb exponentially. And I'm just talking about on the dyno!

I know from the old days that it takes 40hp to run thru a TH400 and 30hp for a TH350. That will be the same for any FWD transmission, the smaller lighter ones will tka e less hp and the big, heavy-*** 4T80E probably more than even the TH400!

So, 500whp + 50hp trans (conservative) + 25hp driveline + 20hp wheels = ~575hp or so...

#146

know from the old days that it takes 40hp to run thru a TH400 and 30hp for a TH350. That will be the same for any FWD transmission, the smaller lighter ones will tka e less hp and the big, heavy-A$$ 4T80E probably more than even the TH400!

So, 500whp + 50hp trans (conservative) + 25hp driveline + 20hp wheels = ~575hp or so...

So, 500whp + 50hp trans (conservative) + 25hp driveline + 20hp wheels = ~575hp or so...

#147

Senior Member

Posts like a Turbo

Join Date: Jan 2005

Location: Hanoverpark/palatine IL, wrenchin' and cursin'

Posts: 247

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by pontiacjeff

Now all I need is .....fuel rails. I still have alot of work to do at the shop, but I really need ot get it done soon.

i ordered the weld on -6 fittings for the -8 rails and i just wanted to dbl check you have the egr deleted right? do you have the 105 or 140amp alternator?

i also wanted to know if your doing parallel flow (dual port fpr) or series flow rail plumbing?

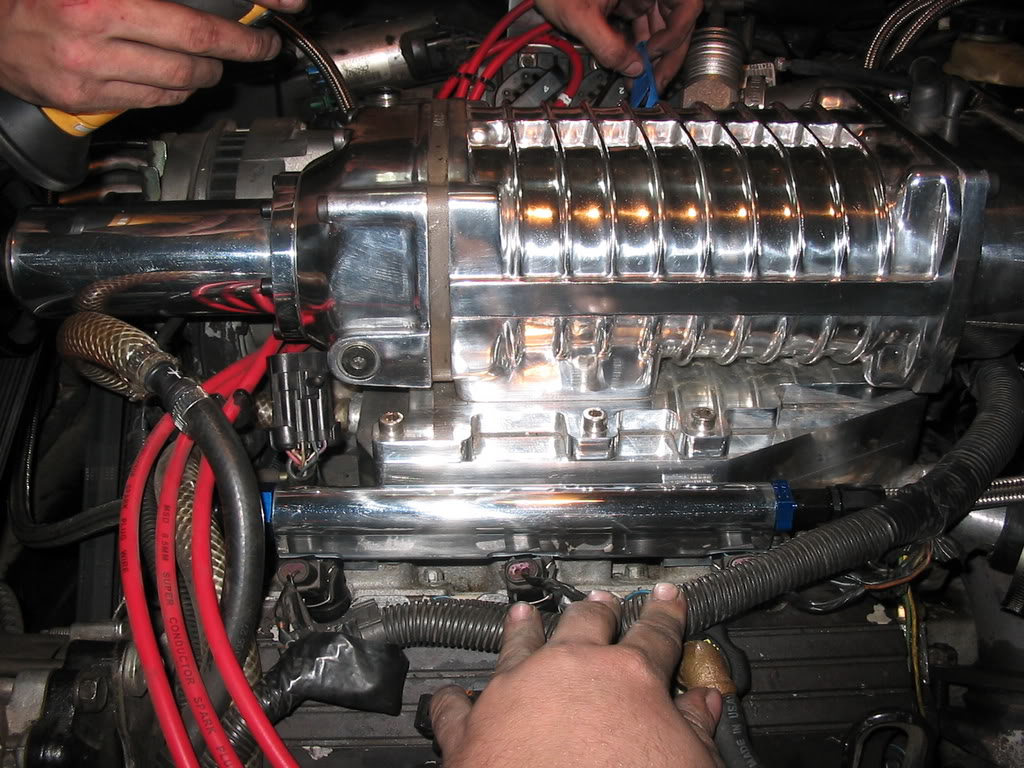

just so you can see em

#148

Senior Member

Posts like a Turbo

Thread Starter

Join Date: Jan 2005

Location: Atlanta, GA. USA

Posts: 368

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Turbocharged400sbc

Originally Posted by pontiacjeff

Now all I need is .....fuel rails. I still have alot of work to do at the shop, but I really need ot get it done soon.

i ordered the weld on -6 fittings for the -8 rails and i just wanted to dbl check you have the egr deleted right? do you have the 105 or 140amp alternator?

i also wanted to know if your doing parallel flow (dual port fpr) or series flow rail plumbing?

Are the rails tapped for screw-in fittings? You said they are 1/2" id, will they accept a 9/16 straight oring screw-in -6 or -8 male? I assume this is how they work. Ifnot, let me know.

I have the big-*** 140amp alt.

I started the turbo i/c last night and today. I got the top (inlet) tank made and it'* off to the welder Friday. I have to build my i/c'* one step at a time or all the pieces drive me nuts trying to mock up templates and pieces holding everything in place and trimming to fit...

While it'* being welded tomorrow, I'll be finishing the wood plates for the */c i/c. I'll have it finished tomorrow and the */c back on, then I'll be waiting on fuel rails.

I ordered a new Powerbond 8-rib crank pulley from ZZP. It'll be here tomorrow and I'll get it on, too.

How long do you expect the fuel rails will take? I had almost decided to just cut and flare the stock rail for now. Maybe I really should just do that... LMK.

#149

Senior Member

Posts like a Turbo

Join Date: Jan 2005

Location: Hanoverpark/palatine IL, wrenchin' and cursin'

Posts: 247

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by pontiacjeff

If I buy your rails, I'll definately tee off for parallel flow and run a dp regulator. Are you welding them? I don't have a tig (or maybe I'm not sure what you are talking about...)

Are the rails tapped for screw-in fittings? You said they are 1/2" id, will they accept a 9/16 straight oring screw-in -6 or -8 male? I assume this is how they work. Ifnot, let me know.

I have the big-A$$ 140amp alt.

I started the turbo i/c last night and today. I got the top (inlet) tank made and it'* off to the welder Friday. I have to build my i/c'* one step at a time or all the pieces drive me nuts trying to mock up templates and pieces holding everything in place and trimming to fit...

While it'* being welded tomorrow, I'll be finishing the wood plates for the */c i/c. I'll have it finished tomorrow and the */c back on, then I'll be waiting on fuel rails.

I ordered a new Powerbond 8-rib crank pulley from ZZP. It'll be here tomorrow and I'll get it on, too.

How long do you expect the fuel rails will take? I had almost decided to just cut and flare the stock rail for now. Maybe I really should just do that... LMK.

Are the rails tapped for screw-in fittings? You said they are 1/2" id, will they accept a 9/16 straight oring screw-in -6 or -8 male? I assume this is how they work. Ifnot, let me know.

I have the big-A$$ 140amp alt.

I started the turbo i/c last night and today. I got the top (inlet) tank made and it'* off to the welder Friday. I have to build my i/c'* one step at a time or all the pieces drive me nuts trying to mock up templates and pieces holding everything in place and trimming to fit...

While it'* being welded tomorrow, I'll be finishing the wood plates for the */c i/c. I'll have it finished tomorrow and the */c back on, then I'll be waiting on fuel rails.

I ordered a new Powerbond 8-rib crank pulley from ZZP. It'll be here tomorrow and I'll get it on, too.

How long do you expect the fuel rails will take? I had almost decided to just cut and flare the stock rail for now. Maybe I really should just do that... LMK.

the -8 bore is .700 and uses the 3/4 -8 o ring thread the -8 to -6 90* fitting clears the 140amp fine but the alternator has to be installed after the rails for tightening of the an hose fitting to the end, you can see it in this pic

i can have them taped etc in less than a week but i'm still finishing my master jigs for the mounting brackets and the jig for the 8-32 screws that thread into the rail base.

thats whats taking me so long (aside from wayyyy too many 14hr workdays lately (busy season this year!)

but it means i can get my new lathe

#150

PopaDopaDo

True Car Nut

Thanks for the education, sorry if I came off offensive.

I don't know much about trannies, as you can probably tell.

That would only be 17% loss. You think thats realistic?

I thought the 4t80e had 24% loss; that translates to ~650 crank HP if you get ~500 at the tires.

And if I made 1000hp at the crank, I would lose 240hp?

I don't buy into the percent losses. At stock hp levels it'* extrapolated by taking the output at the wheels of a stock engine and doing the math to come up with something close to the factory hp rating. It doesn't work when you start making alot of hp. It takes the same amount of hp to turn a 4T80E, regardless of the input power. Same for any transmission, auto or manual. It takes the same amount of hp to turn the axles, spin the hubs, rotate the wheels, across a general speed range regardless of the input power. Where things get more inefficient is at speeds over 100mph. When all that mass of axles, bearings, wheels, is turning at that speed, power loss percentages climb exponentially. And I'm just talking about on the dyno!

I know from the old days that it takes 40hp to run thru a TH400 and 30hp for a TH350. That will be the same for any FWD transmission, the smaller lighter ones will tka e less hp and the big, heavy-A$$ 4T80E probably more than even the TH400!

So, 500whp + 50hp trans (conservative) + 25hp driveline + 20hp wheels = ~575hp or so...

I don't know much about trannies, as you can probably tell.

Originally Posted by pontiacjeff

Originally Posted by popatim

My goal is 500whp, which is about 600 at the crank.

I thought the 4t80e had 24% loss; that translates to ~650 crank HP if you get ~500 at the tires.

I don't buy into the percent losses. At stock hp levels it'* extrapolated by taking the output at the wheels of a stock engine and doing the math to come up with something close to the factory hp rating. It doesn't work when you start making alot of hp. It takes the same amount of hp to turn a 4T80E, regardless of the input power. Same for any transmission, auto or manual. It takes the same amount of hp to turn the axles, spin the hubs, rotate the wheels, across a general speed range regardless of the input power. Where things get more inefficient is at speeds over 100mph. When all that mass of axles, bearings, wheels, is turning at that speed, power loss percentages climb exponentially. And I'm just talking about on the dyno!

I know from the old days that it takes 40hp to run thru a TH400 and 30hp for a TH350. That will be the same for any FWD transmission, the smaller lighter ones will tka e less hp and the big, heavy-A$$ 4T80E probably more than even the TH400!

So, 500whp + 50hp trans (conservative) + 25hp driveline + 20hp wheels = ~575hp or so...