Top End Rebuild

#111

Senior Member

True Car Nut

Thread Starter

Join Date: Apr 2004

Location: Three Oaks, Michigan

Posts: 4,879

Likes: 0

Received 0 Likes

on

0 Posts

Hot damn am I dumb. I don't know what I was thinking in that last post. Shims? That will only make the problem worse making the pressure on the lifters all the more greater. I looked at the cost of new lifters.. and I KNOW I cannot fit those in my budget. I looked at some new rods and they seem affordable. Maybe not quite what I wanted to drop cash on, but yeah.. they seem to be the viable option here. I'm thinking [since the rods are longer than my micrometer can measure] take one of my rods in with me, and compare it against others. I know what .085" looks like.. so I am thinking perhaps to grab something a little under .085" so that I try to keep the closest to stock adjustments in the lifters and rockers. The other viable option is to drill out the hole [the countersink hole] in the rockers that the ball of the rods sit in. This worries me because it may compromise the structural integrity of the rockers.. and maybe under high load conditions could bend it or send a rod through it.. and I KNOW that isn't good. At this point I am not longer sure. I'm going to make a few phone calls tonight, and see if I can come up with somebody who knows the adjustability of the lifters.. or find a vet engine builder who knows their ****.

-justin

-justin

#112

Senior Member

True Car Nut

Join Date: Feb 2003

Location: Philly

Posts: 4,508

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by opensourceguy

Hmm.. that'* a good idea. Do they make shims for lifters? Because I am sure you know that the lifters have a seat in them and I doubt my rods would stay in there without them. How much extra lift are we talking about here? I would like a little extra lift, because I make so little as it is, and that will probably be the biggest bottleneck as far as flow [minus the headers].

And to be honest, my valve tap wasn't all that bad. It was noticable on the rear bank, but only if you were listening for it.

I'm thinking some larger lifters [like you suggested] may be the best option. I'm not sure how I could go about purchasing them, without having them in front of me and measuring them. Which would probably be difficult since I doubt Autozone would allow me to go through their entire inventory of lifters [if they even had any]. I'll look into it. Maybe Comp Cams lists their lengths, if not --perhaps I can call their overseas tech support, where 3" sounds like tree.

-justin

And to be honest, my valve tap wasn't all that bad. It was noticable on the rear bank, but only if you were listening for it.

I'm thinking some larger lifters [like you suggested] may be the best option. I'm not sure how I could go about purchasing them, without having them in front of me and measuring them. Which would probably be difficult since I doubt Autozone would allow me to go through their entire inventory of lifters [if they even had any]. I'll look into it. Maybe Comp Cams lists their lengths, if not --perhaps I can call their overseas tech support, where 3" sounds like tree.

-justin

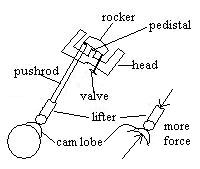

Sorry man, i'm kinda bad at explaining stuff sometimes. With the heads decked .085 the rocker arm is that much closer to the cam lobe. In theroy that should give you more lift. but i don't think the lifters are going to be able to pump up as they should with that much more force on them. So, i'd suggest getting shorter pushrods or maybe getting some high rockwell/bernill hardness # .030-.060 steel shims to place in between the rocker pedistal and the head, that way it will put the distance between the rocker arm and cam lobe back into a rocker friendly range. <--- i don't know if that'* a good practice or not, just something i was thinking of.

Here'* a crappy mspaint pic:

#113

Senior Member

True Car Nut

Thread Starter

Join Date: Apr 2004

Location: Three Oaks, Michigan

Posts: 4,879

Likes: 0

Received 0 Likes

on

0 Posts

Wow dude, good timing. Like 4 minutes ago I just figured out what you were talking about. Yes, it seems as though that is a perfectly find practice. Crane Cams has the instructions [with the suggestion of the shim method]. So, it seems that'* what I will do. Because I betcha any money those shims will be a helluva lot less than new rods. I'm still looking for those shims [haven't started actually.. so yeah]. And no worries about the instructions, I can be a little slow at times. Not your fault.

Here is the article where I found the instructions

http://store.summitracing.com/instructions.asp?File=crn-99277-16(2)1.pdf

-justin

Here is the article where I found the instructions

http://store.summitracing.com/instructions.asp?File=crn-99277-16(2)1.pdf

-justin

#115

Senior Member

True Car Nut

Thread Starter

Join Date: Apr 2004

Location: Three Oaks, Michigan

Posts: 4,879

Likes: 0

Received 0 Likes

on

0 Posts

I found some for Mopar engines.. but I also found a few online shops that specialize in shims and ****. I can give them a call tomorrow and ask for a quote, but I need more info. What metal should I have this made out of, and what should be the thickness to start out with? I'm thinking just because I removed .085" off the heads, doesn't necessarly mean the rockers are .085" closer to the lifters. I'm thinking it will be less, but I could be wrong [don't know trig]. I was thinking something like .015" [seemed to be the most common] and put on .085" to start with, and remove until I feel content. However, a 10 pack of those suckers is $12. That'* expensive since I will probably need 5 per valve, 12 valves that'* $70 right there. For that money I could grab some new rods [which I am sure would be better than all those damn shims].

Is it possible for me to use just generic washers I got from Lowe'*? Because to be honest.. I don't think the valvetrain has that much pressure put on it to the point where those things aren't going to be strong enough to support 25ft lbs of support. But then again I am not thinking of the rocker moving and that force and such [which, to be honest I have no clue where to start with the figures for that].

I also noticed that the majority of valvetrain guides and products are for VW engines. It seems like Volkswagon enthusists are the best valvetrain guys, perhaps? It was quite interesting because I was going to all these type 2 [VW Bus] websites. Mmm.. VW Bus

Oh yeah, let'* party, this has to be one of the top 10 biggest threads here on BC. 8 pages, over 1,000 views, and over 140 posts. Badass **** my friends.

-justin

Is it possible for me to use just generic washers I got from Lowe'*? Because to be honest.. I don't think the valvetrain has that much pressure put on it to the point where those things aren't going to be strong enough to support 25ft lbs of support. But then again I am not thinking of the rocker moving and that force and such [which, to be honest I have no clue where to start with the figures for that].

I also noticed that the majority of valvetrain guides and products are for VW engines. It seems like Volkswagon enthusists are the best valvetrain guys, perhaps? It was quite interesting because I was going to all these type 2 [VW Bus] websites. Mmm.. VW Bus

Oh yeah, let'* party, this has to be one of the top 10 biggest threads here on BC. 8 pages, over 1,000 views, and over 140 posts. Badass **** my friends.

-justin

#116

Senior Member

True Car Nut

Join Date: Feb 2003

Location: Philly

Posts: 4,508

Likes: 0

Received 0 Likes

on

0 Posts

lol i didn't even know this thread got so big till you linked it to me the other day.

Don't get washers from lowes, please? lol The impact strength is not good unless stated otherwise. The washers you want should be a high carbon steel. I'm thinking that if you got the washers to be like .075 (5) that should be great. it would be like just milling your head 10 over.

One thing you might want to do is just mill the head .060 and raise the compression by roughly only one point. Then you would just need 3 or 4 washers which would cost 48 bucks (3 washers). and the milling may cost less. And there would be a much less chance of denotation.

-just a thought

Another thing i was thinking about is when you checked for clearances, was a screwed in spark plug in?

And have you thought about porting your manifolds? I know theres not much to do but if you have someone put the welds on the outside of each tube where it meets the flange, you can grind out the welds on the inside of the ports (going on the ***-umption that a) the welds are on the inside and b) you know someone that will weld it cheap).

Porting your manifolds should help you stay away from knock too.

And don't forget you can port/smooth out your coolant ports too.

Don't get washers from lowes, please? lol The impact strength is not good unless stated otherwise. The washers you want should be a high carbon steel. I'm thinking that if you got the washers to be like .075 (5) that should be great. it would be like just milling your head 10 over.

One thing you might want to do is just mill the head .060 and raise the compression by roughly only one point. Then you would just need 3 or 4 washers which would cost 48 bucks (3 washers). and the milling may cost less. And there would be a much less chance of denotation.

-just a thought

Another thing i was thinking about is when you checked for clearances, was a screwed in spark plug in?

And have you thought about porting your manifolds? I know theres not much to do but if you have someone put the welds on the outside of each tube where it meets the flange, you can grind out the welds on the inside of the ports (going on the ***-umption that a) the welds are on the inside and b) you know someone that will weld it cheap).

Porting your manifolds should help you stay away from knock too.

And don't forget you can port/smooth out your coolant ports too.

#117

Senior Member

True Car Nut

Thread Starter

Join Date: Apr 2004

Location: Three Oaks, Michigan

Posts: 4,879

Likes: 0

Received 0 Likes

on

0 Posts

Umm.. I am porting my manifolds.. porting intake ports, heads [both intake + exhaust], and cleaning up the welds [and lip on rear] headers.

Okay, no Lowe'* washers. Gotcha on that.

No I did not measure the clearances with a spark plug in. You think that may make a difference in the clearance?

I don't know man.. I have my heart set on the 10:1 CR. You think I am pushing it at this point?

-justin

Okay, no Lowe'* washers. Gotcha on that.

No I did not measure the clearances with a spark plug in. You think that may make a difference in the clearance?

I don't know man.. I have my heart set on the 10:1 CR. You think I am pushing it at this point?

-justin

#118

Senior Member

True Car Nut

Join Date: Feb 2003

Location: Philly

Posts: 4,508

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by opensourceguy

Umm.. I am porting my manifolds.. porting intake ports, heads [both intake + exhaust], and cleaning up the welds [and lip on rear] headers.

Originally Posted by opensourceguy

No I did not measure the clearances with a spark plug in. You think that may make a difference in the clearance?

Originally Posted by opensourceguy

I don't know man.. I have my heart set on the 10:1 CR. You think I am pushing it at this point?

that .6 diffrence isn't going to mean anything if you have KR. I mean i dunno it'* up to you but IMHO i think that you should do everything you can to get the washers.

What kind of timing advance is stock for you car?

#119

Senior Member

True Car Nut

Thread Starter

Join Date: Apr 2004

Location: Three Oaks, Michigan

Posts: 4,879

Likes: 0

Received 0 Likes

on

0 Posts

To be honest, I have no clue about the plug. I'm so god damn tired, I don't feel like checking right now. I'll look tomorrow and see if I need to do the play-doh test with a plug.

I'm not sure KR will be that big of a problem.. like I mean I will have it, I know; but I don't know. My ECU doesn't display fuel trims or **** like that. RPM, gear, TCC on/off, and IAC counts. That'* about it [I know there are more, just making a point here]. So I would have no way of testing that. I will have some very good flowing heads.. maybe not crazy good, but I am going to say pretty good, because well they are enlarged quite a bit. Plus everything is being smoothed out, rough castings and all that horrible ****.

I'm not sure what you mean about the .6 difference.. could you please elaborate on .6 difference of what?

Timing advance? Beats the **** out of me. I don't even think that is in my FSM [wherever that may be].

In your dead honest opinion, no scientific hypothetical whatnot bullshit; would you recommend this? Is this really worth it? Other than "How much is this going to cost" that has been my biggest question [and fear]. I know it may be kinda dumb, but my goal right now, is to go 25mph in 1st gear, then floor it and be able to light 'er up. Right now on a good day I can chirp the tires and snap your neck back [well, maybe not right now ].

].

I'm not trying to put down anyone.. but I really need someone who knows their **** at this point. I bow down to you guys, because I mean I know nothing in comparison to all you guys.. but I think 95nasta is my window into the house of engine building knowledge.

-justin

I'm not sure KR will be that big of a problem.. like I mean I will have it, I know; but I don't know. My ECU doesn't display fuel trims or **** like that. RPM, gear, TCC on/off, and IAC counts. That'* about it [I know there are more, just making a point here]. So I would have no way of testing that. I will have some very good flowing heads.. maybe not crazy good, but I am going to say pretty good, because well they are enlarged quite a bit. Plus everything is being smoothed out, rough castings and all that horrible ****.

I'm not sure what you mean about the .6 difference.. could you please elaborate on .6 difference of what?

Timing advance? Beats the **** out of me. I don't even think that is in my FSM [wherever that may be].

In your dead honest opinion, no scientific hypothetical whatnot bullshit; would you recommend this? Is this really worth it? Other than "How much is this going to cost" that has been my biggest question [and fear]. I know it may be kinda dumb, but my goal right now, is to go 25mph in 1st gear, then floor it and be able to light 'er up. Right now on a good day I can chirp the tires and snap your neck back [well, maybe not right now

I'm not trying to put down anyone.. but I really need someone who knows their **** at this point. I bow down to you guys, because I mean I know nothing in comparison to all you guys.. but I think 95nasta is my window into the house of engine building knowledge.

-justin

#120

Senior Member

True Car Nut

Join Date: Feb 2003

Location: Philly

Posts: 4,508

Likes: 0

Received 0 Likes

on

0 Posts

Well I honestly don't know a whole lot about engine building, thanks but don't give me too much credit. lol I'm a college kid that wants to make his car fast and has done enough research to do what'* in the sig and maybe a little more.

So, as to if i would do it or not i wouldn't be able to give you a 100% backed answer.

I just can't say for sure but i'd hate to see you get a bunch of KR and have less power than when you started with.

I know your gonna have better flowing ports/manifolds but they will only flow as much as your cam/valvetrain will let them. So, yeah ultimatley your going to be flowing better but like you said your stock cam/valvetrain is the bottleneck.

Ohh the .6 i was talking about was compression going from 10.1:1(.085 off) to 9.5:1 (.060 off) wait, it would be 9.4:1 well .7 difference i guess. Those numbers are rough anyways. I just think it would be safer to be around 9.5ish, not as big of a worry about KR, possibly less money to mill, and more money torwards the shims.

Another thing i think you've talked about before is the lower intake manifold lining up right. anything closer to .030 is safer beyond that i just have no idea, just look at 1/16" on a ruler, that'* a little more than how much more your lower intake gaskets are going to have to compress to line up if you go .060. .060 looks safer in that respect as well.

Try and talk to a real engine builder that'* been in the business forever.

And test out that plug situation cause that would be one thing you won't want to overlook.

So, as to if i would do it or not i wouldn't be able to give you a 100% backed answer.

I just can't say for sure but i'd hate to see you get a bunch of KR and have less power than when you started with.

I know your gonna have better flowing ports/manifolds but they will only flow as much as your cam/valvetrain will let them. So, yeah ultimatley your going to be flowing better but like you said your stock cam/valvetrain is the bottleneck.

Ohh the .6 i was talking about was compression going from 10.1:1(.085 off) to 9.5:1 (.060 off) wait, it would be 9.4:1 well .7 difference i guess. Those numbers are rough anyways. I just think it would be safer to be around 9.5ish, not as big of a worry about KR, possibly less money to mill, and more money torwards the shims.

Another thing i think you've talked about before is the lower intake manifold lining up right. anything closer to .030 is safer beyond that i just have no idea, just look at 1/16" on a ruler, that'* a little more than how much more your lower intake gaskets are going to have to compress to line up if you go .060. .060 looks safer in that respect as well.

Try and talk to a real engine builder that'* been in the business forever.

And test out that plug situation cause that would be one thing you won't want to overlook.