Making Homemade Gaskets

#12

Senior Member

Certified Car Nut

Thread Starter

Join Date: Oct 2002

Posts: 11,308

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by willwren

Pete, let'* see some pics of what you have for a gasket and EGR tube.

#13

Senior Member

Certified Car Nut

Thread Starter

Join Date: Oct 2002

Posts: 11,308

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by MOS95B

www.partsamerica.com has the real gaskets for as low as $2.79.

EGR VALVE gasket:

#14

Junior Member

Posts like a Ricer Type-R

Pete, you're talking about where the pipe goes into the SC? You shouldn't need a gasket there.

I needed one, as my Gen2 EGR tube is a smaller diameter than the port on the Gen3 Supercharger, so I just cut a custom one from another standard EGR gasket:

Stock applications shouldn't need to do this. This should only be needed for a Gen2 to Gen3 swap.

I needed one, as my Gen2 EGR tube is a smaller diameter than the port on the Gen3 Supercharger, so I just cut a custom one from another standard EGR gasket:

Stock applications shouldn't need to do this. This should only be needed for a Gen2 to Gen3 swap.

#15

Senior Member

Certified Car Nut

Thread Starter

Join Date: Oct 2002

Posts: 11,308

Likes: 0

Received 0 Likes

on

0 Posts

Bill, I just don't want to risk cracking the tube since it doesn't sit flush on its own. If I tighten it too much I'm afraid it will push the flared part unevenly around the opening and it may crack it. It may not, but since I don't know for sure I don't want to try. I hope I'm making sense when I am explaining why I could use a gasket.

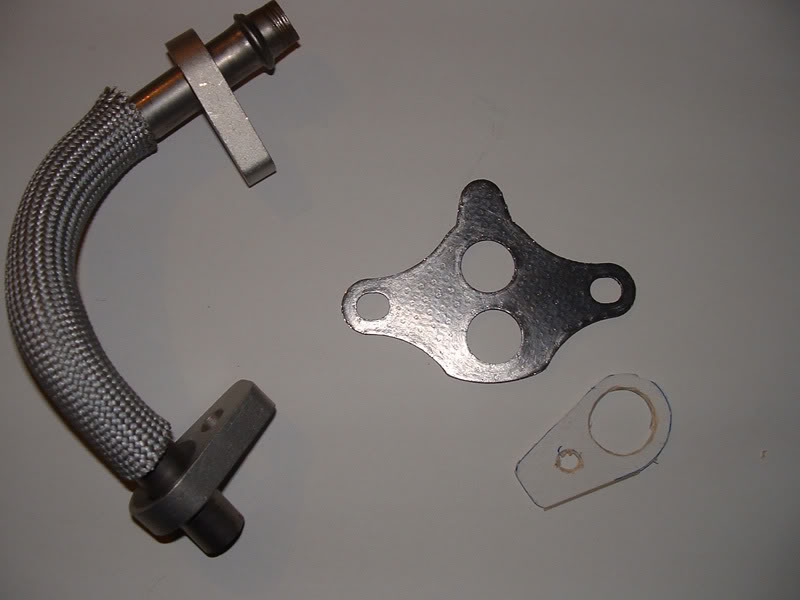

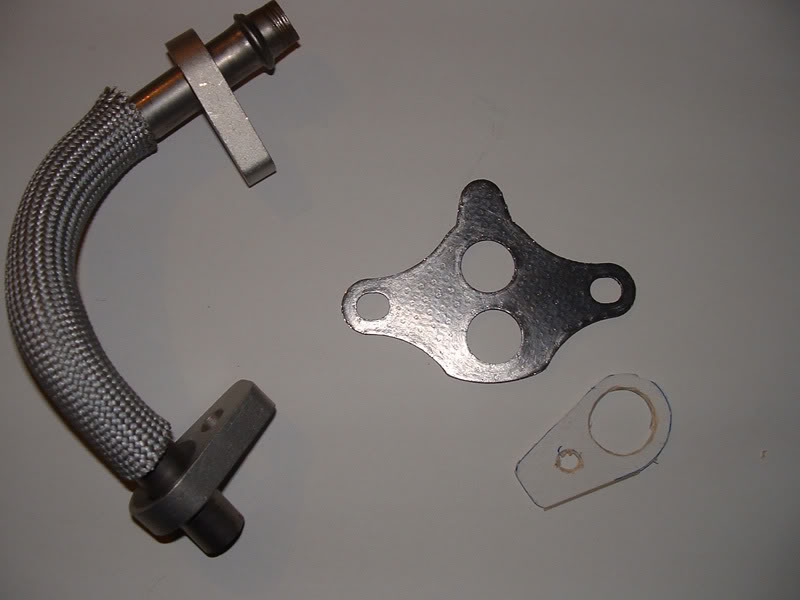

Ok, here are some pics.

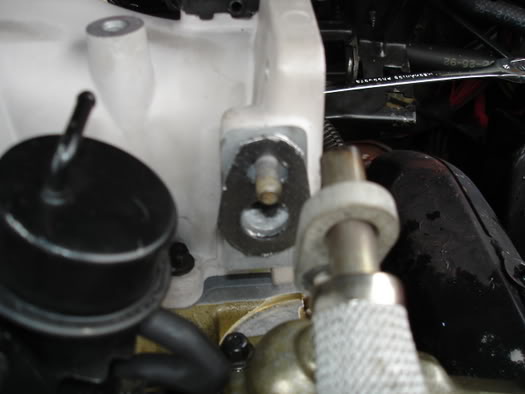

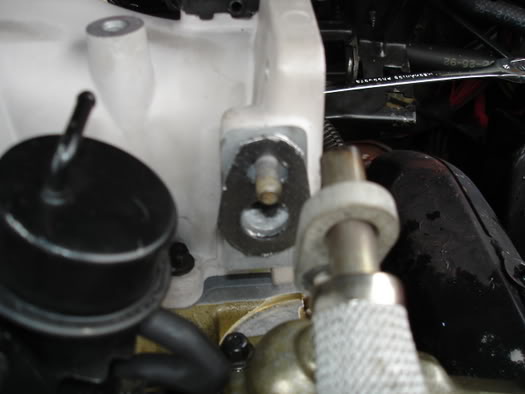

This shows how the 'flare' is not fully flush within the recess of the bracket. The stock tube was fully recessed so it sat flat against both surfaces. The stock flare is completely flat, this one is rounded.

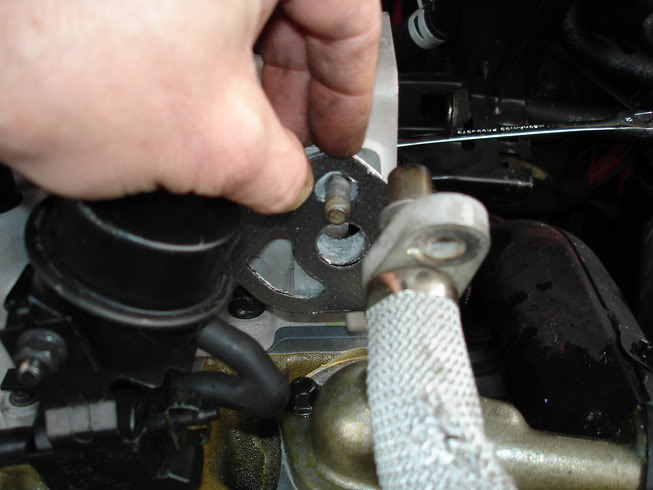

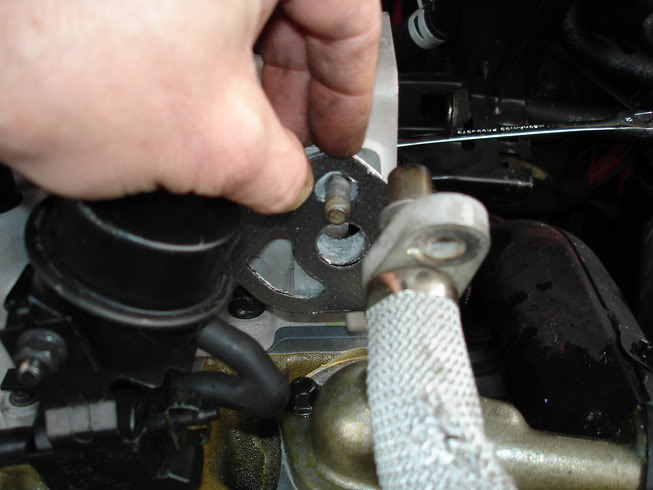

I bought an EGR valve gasket and I think I will have enough material for the top and bottom. The white gasket is a quick test piece I made of illustration board. It'* the absolute most I would need for the gasket.

This is one of the ways I can make a gasket.

Ok, here are some pics.

This shows how the 'flare' is not fully flush within the recess of the bracket. The stock tube was fully recessed so it sat flat against both surfaces. The stock flare is completely flat, this one is rounded.

I bought an EGR valve gasket and I think I will have enough material for the top and bottom. The white gasket is a quick test piece I made of illustration board. It'* the absolute most I would need for the gasket.

This is one of the ways I can make a gasket.

#16

Senior Member

Certified Car Nut

Thread Starter

Join Date: Oct 2002

Posts: 11,308

Likes: 0

Received 0 Likes

on

0 Posts

I made a couple new holes in the gasket. Kind of a pain with the material, but it seems like it'* going to work. I'm going to go try it out.

EDIT: Worked great! The gaskets were enough to cushion the flares and keep it from pinching tight. That solves my 5 month+ long vacuum problem, as far as I know..

EDIT: Worked great! The gaskets were enough to cushion the flares and keep it from pinching tight. That solves my 5 month+ long vacuum problem, as far as I know..

#17

Junior Member

Posts like a Ricer Type-R

Pete, it'* designed to NOT use a gasket. You may induce leaks. That fitting is what you call a 'compression' fitting. It'* designed NOT to fit flush, so the clamping force seals it.

I would strongly recommend removing the gasket you made. I HAVE to use one because my stock tube is too small for the Gen3 SC I swapped to.

I would strongly recommend removing the gasket you made. I HAVE to use one because my stock tube is too small for the Gen3 SC I swapped to.

#18

Senior Member

Posts like a Camaro

Join Date: Dec 2005

Location: Clovis, CA

Posts: 851

Likes: 0

Received 0 Likes

on

0 Posts

I'm always making my own gaskets for the little mower engines. I buy an OEM gasket to use as a pattern and then I get some gasket material and make duplicates; as long as they're not too intricate. I've got a full set of hole punches too. They're the kind that you strike with a hammer like a pin punch. If you can't find the automotive hole punches, the kind like at the leather supply shop work excellent. Oh yeah, I cut them out with an X-ACTO knife.

One time I bought a Briggs & Stratton gasket that was missing a hole for a carburetor screw.

One time I bought a Briggs & Stratton gasket that was missing a hole for a carburetor screw.

#19

Junior Member

Join Date: May 2006

Location: BonnevilleHell

Posts: 0

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by bonnie94ssei

This shows how the 'flare' is not fully flush within the recess of the bracket. The stock tube was fully recessed so it sat flat against both surfaces. The stock flare is completely flat, this one is rounded.

#20

Senior Member

Certified Car Nut

Thread Starter

Join Date: Oct 2002

Posts: 11,308

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by willwren

Pete, it'* designed to NOT use a gasket. You may induce leaks. That fitting is what you call a 'compression' fitting. It'* designed NOT to fit flush, so the clamping force seals it.

I would strongly recommend removing the gasket you made. I HAVE to use one because my stock tube is too small for the Gen3 SC I swapped to.

I would strongly recommend removing the gasket you made. I HAVE to use one because my stock tube is too small for the Gen3 SC I swapped to.

I had no leaks today, and the car drove better than it has been for a while actually.

But I'll go ahead and try again without the gaskets. My gaskets were just so I didn't waste $40 on a pipe that I could crack by tightening it incorrectly, since I don't have another $40.

It'* a thin, soft, steel