Pulley on down......

#4

Junior Member

Posts like a Ricer Type-R

He'* just finding the limits, guys. And a 3.3 tomorrow doesn't mean a 3.3 at Woodburn in July. Paul is very well aware of that fact.  He'* kinda been playing this game for about 4 years.

He'* kinda been playing this game for about 4 years.

He'* kinda been playing this game for about 4 years.

He'* kinda been playing this game for about 4 years.

#5

Oh Bill, don't make me sound so devious.

Yes it did adjust to the 3.4 after about an hour of driving.

Tomorrow I will try and do the same for an hour with the 3.3.

At the next opportunity, I will try the 3.2

.......and then.......

the 3.1

.......and then.......

the 3.0

......and then........

the 2.9

Yes it did adjust to the 3.4 after about an hour of driving.

Tomorrow I will try and do the same for an hour with the 3.3.

At the next opportunity, I will try the 3.2

.......and then.......

the 3.1

.......and then.......

the 3.0

......and then........

the 2.9

#6

Senior Member

True Car Nut

Join Date: Dec 2002

Location: Sauk Centre, MN

Posts: 5,459

Likes: 0

Received 0 Likes

on

0 Posts

You have me salivating for some run time in my 99. I've put 40 miles on it since I got it roadable.

I have the 3.4" on the SC now, but the S1X should give me a chance @ the 3.3". Gotta ditch the P-log and PEM for some of these:

http://cgi.ebay.com/ebaymotors/1997-...spagenameZWDVW

Then, dyno, then GEN V time!!! And back to the 3.4 probably.

And back to the 3.4 probably.

I have the 3.4" on the SC now, but the S1X should give me a chance @ the 3.3". Gotta ditch the P-log and PEM for some of these:

http://cgi.ebay.com/ebaymotors/1997-...spagenameZWDVW

Then, dyno, then GEN V time!!!

#9

Junior Member

Posts like a Ricer Type-R

The two most succesfull ported Gen3'* (one M62 and one M90) that I know of

were able to drop 0.2" on pulley size without KR, and also a Gen2 M62 before

that. From all the reading I've done, this is NOT attributed to the outlet as much

as it is the inlet, which most off-the-shelf porting sources don't do.

I'm quite curious to see if your GenV responds the same as the SC'* Boosty and

I have done, as well as seeing if Harofreak'* and Shadd'* SC'* do the same as

well.

So far, the inlet porting seems to have reduced boost charge temps enough to allow

us to drop 0.2" in pulley diameter without an increase in KR. This is why boosty

was able to run a 3.2" pulley on PEM'* before he did the rockers. And why I was

able to run a 2.2", then a 2.0" on a Gen3 setup that would have normally run with a

2.5".

I may use my 'old' ported Gen3 on the 95 to prove that point further, with no changes

to the exhaust at all. But that'll be after the next ported Gen3 goes on the Zilla for testing.

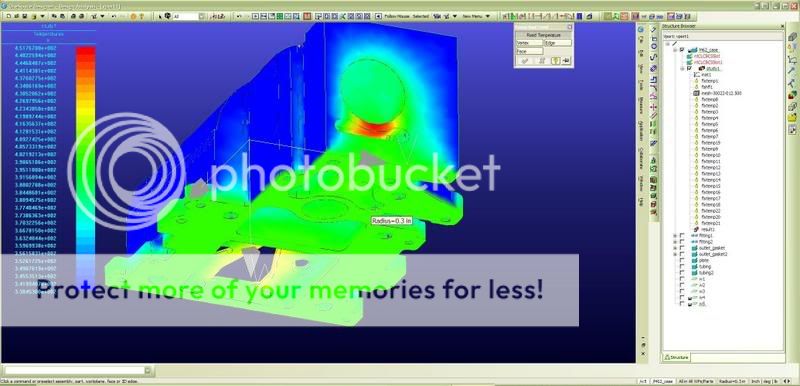

Every thermal analysis model I've seen or performed myself has shown the inlet to

be the hot spot. None of the models took into account the surface roughness, but

all of them showed the inlet being the hottest if it were SMOOTH. The roughness

only hurts more. Smoothing this out is a big benefit.

This analysis was done by a group of college engineering students back in 2002 IIRC:

You can see that the inlet is the hottest surface. Black being coolest, white

being hottest. When I ran the same model several years later with a much better

CAD package, I got this:

Paul, I'll be very curious to see if the GenV proves to follow along the same path

after smoothing, porting, and polishing. It wasn't quite as rough as the M62'* and

M90'* I've done, but it was similar. I'd expect you to run a smaller pulley after that

work than one would normally expect.

were able to drop 0.2" on pulley size without KR, and also a Gen2 M62 before

that. From all the reading I've done, this is NOT attributed to the outlet as much

as it is the inlet, which most off-the-shelf porting sources don't do.

I'm quite curious to see if your GenV responds the same as the SC'* Boosty and

I have done, as well as seeing if Harofreak'* and Shadd'* SC'* do the same as

well.

So far, the inlet porting seems to have reduced boost charge temps enough to allow

us to drop 0.2" in pulley diameter without an increase in KR. This is why boosty

was able to run a 3.2" pulley on PEM'* before he did the rockers. And why I was

able to run a 2.2", then a 2.0" on a Gen3 setup that would have normally run with a

2.5".

I may use my 'old' ported Gen3 on the 95 to prove that point further, with no changes

to the exhaust at all. But that'll be after the next ported Gen3 goes on the Zilla for testing.

Every thermal analysis model I've seen or performed myself has shown the inlet to

be the hot spot. None of the models took into account the surface roughness, but

all of them showed the inlet being the hottest if it were SMOOTH. The roughness

only hurts more. Smoothing this out is a big benefit.

This analysis was done by a group of college engineering students back in 2002 IIRC:

You can see that the inlet is the hottest surface. Black being coolest, white

being hottest. When I ran the same model several years later with a much better

CAD package, I got this:

Originally Posted by willwren

What'* the hottest surface? The INLET. Not the outlet. Why? Restriction/friction

of airflow. To be honest, this is a very simple model. It doesn't have the cooling

ports, and some of the conditions may be based on theory, rather than reality. So

we take this data as a starting point, and try to refine the model (this analysis was

done by a group of college engineering students at least 3 or 4 years ago.

Fast forward to the current state of the Zilla:

See the little temperature strips? There are 9 of them on the SC, Nosedrive, TB,

and LIM. Why? I wanted to know not only WHAT temperatures were typical in

different driving conditions, but also HOW it heats up. What'* hot first? Where

does the heat start, and how does the SC react during heatsoak? Does the

coolant actually HELP?

So then I made a model.

That was a long time ago, and for another purpose as well, but a good 3D model is

the starting point for a good thermal analysis job.

So I took everything I learned from the original thermal analysis (top image in this topic),

and everything I learned from REAL data from my own car (coolant temps, stuck-on

thermal temp strips, and IR heat analysis) in multiple conditions. Different ambient air

temps, wet weather, dry weather, street conditions, long trips, and track.

Now let'* apply all THAT to the 3D model WITHOUT coolant flow (temps are typical on

a warmed up engine after about 15 minutes of driving in ambient 60°F air, 200° LIM):

The dark blue is constrained to 150°F (338Kelvin) to represent engine bay ambient

temps, and the bottom surface is constrained to typical LIM temps. As you can see,

the BOTTOM of the inlet is the hottest surface. This is what pre-heats your incoming

air for you. Nice, huh?

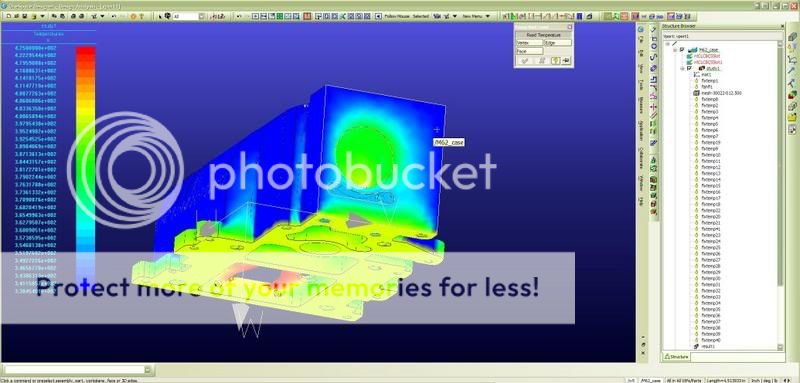

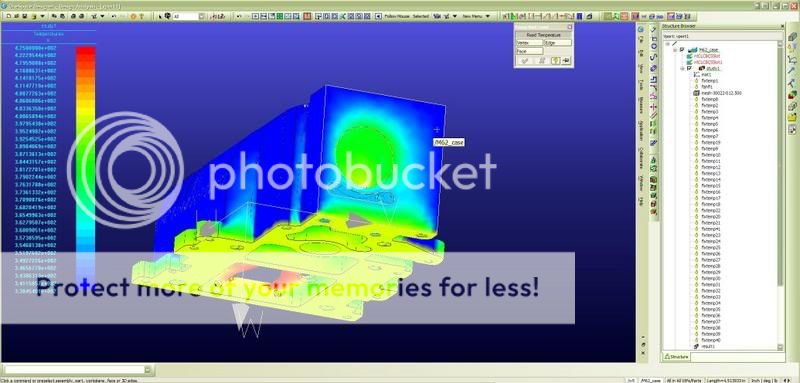

Now let'* induce some coolant flow and kick up the incoming air temp a bit to REALLY

see what'* going on (85° ambient air, 180° coolant temp in the SC coolant ports, 250°F

LIM temp):

See the positive result in the inlet despite the increased IAT and LIM temps?

Coolant flow controls it. See the outlet edges got hotter? That'* why we smooth them.

They're 'factory sharp' but not 'factory rough' in this model.

Now to be honest, there are other factors at work here, but I think I've captured the

critical data very well in these models. On a track, with sufficient cooling, you'll be OK.

SC temps don't spike at the track until AFTER the run. But if you drive your car daily,

you need the coolant. And you can STILL cool down between runs at the track. You've

lost nothing.

Ideal solution? A seperately cooled interface plate between the SC and LIM, that routes

coolant (not engine coolant) through the plate beneath the SC, and through the SC to the

TB. Something like this:

Further incoming air temp improvements are the direct result of polishing your SC inlet.

As a point of comparison:

My Gen3 M62 inlet and TB run 15° cooler than Matt'* Gen3 M90, despite the fact that

I was moving far more air with a 2.0" pulley than his stock 3.8" pulley. This is a direct

result of polishing the rough inlet surface left over from the casting process.

This was after an extended high-throttle side-by-side run in 106°F ambient conditions.

I hope I've answered the question from this topic, at least with regards to the L67'* out

there. The data is going to come out differently for L27'* and L36'*, as the inlets won't

be as hot to begin with. But it'* something to chew on.

of airflow. To be honest, this is a very simple model. It doesn't have the cooling

ports, and some of the conditions may be based on theory, rather than reality. So

we take this data as a starting point, and try to refine the model (this analysis was

done by a group of college engineering students at least 3 or 4 years ago.

Fast forward to the current state of the Zilla:

See the little temperature strips? There are 9 of them on the SC, Nosedrive, TB,

and LIM. Why? I wanted to know not only WHAT temperatures were typical in

different driving conditions, but also HOW it heats up. What'* hot first? Where

does the heat start, and how does the SC react during heatsoak? Does the

coolant actually HELP?

So then I made a model.

That was a long time ago, and for another purpose as well, but a good 3D model is

the starting point for a good thermal analysis job.

So I took everything I learned from the original thermal analysis (top image in this topic),

and everything I learned from REAL data from my own car (coolant temps, stuck-on

thermal temp strips, and IR heat analysis) in multiple conditions. Different ambient air

temps, wet weather, dry weather, street conditions, long trips, and track.

Now let'* apply all THAT to the 3D model WITHOUT coolant flow (temps are typical on

a warmed up engine after about 15 minutes of driving in ambient 60°F air, 200° LIM):

The dark blue is constrained to 150°F (338Kelvin) to represent engine bay ambient

temps, and the bottom surface is constrained to typical LIM temps. As you can see,

the BOTTOM of the inlet is the hottest surface. This is what pre-heats your incoming

air for you. Nice, huh?

Now let'* induce some coolant flow and kick up the incoming air temp a bit to REALLY

see what'* going on (85° ambient air, 180° coolant temp in the SC coolant ports, 250°F

LIM temp):

See the positive result in the inlet despite the increased IAT and LIM temps?

Coolant flow controls it. See the outlet edges got hotter? That'* why we smooth them.

They're 'factory sharp' but not 'factory rough' in this model.

Now to be honest, there are other factors at work here, but I think I've captured the

critical data very well in these models. On a track, with sufficient cooling, you'll be OK.

SC temps don't spike at the track until AFTER the run. But if you drive your car daily,

you need the coolant. And you can STILL cool down between runs at the track. You've

lost nothing.

Ideal solution? A seperately cooled interface plate between the SC and LIM, that routes

coolant (not engine coolant) through the plate beneath the SC, and through the SC to the

TB. Something like this:

Further incoming air temp improvements are the direct result of polishing your SC inlet.

As a point of comparison:

My Gen3 M62 inlet and TB run 15° cooler than Matt'* Gen3 M90, despite the fact that

I was moving far more air with a 2.0" pulley than his stock 3.8" pulley. This is a direct

result of polishing the rough inlet surface left over from the casting process.

This was after an extended high-throttle side-by-side run in 106°F ambient conditions.

I hope I've answered the question from this topic, at least with regards to the L67'* out

there. The data is going to come out differently for L27'* and L36'*, as the inlets won't

be as hot to begin with. But it'* something to chew on.

after smoothing, porting, and polishing. It wasn't quite as rough as the M62'* and

M90'* I've done, but it was similar. I'd expect you to run a smaller pulley after that

work than one would normally expect.

#10

Good response Bill and exactly the reason I think I can, against recommendations to run .2 pulley size larger with the Gen V, run the same size I was able to get away with before with the Gen 3.

I had been running with the 3.2" before with 0 KR.

I think I should be able to run a 3.2" now with the Gen V, thanks to the porting and polishing and I'm going to prove it.

I don't want to "have to" use the water injection until I go smaller, or bump up the timing, for extracuricular racing activities.

for extracuricular racing activities.

Remember I ran the 3.1" for a solid year back in 05 on 94 octane with no problems and still took home the prize for quickest 1/4 mi run at our Meet.

Bad news, this morning. :( The Fog has left the roads wet

If they don't dry out within the next 3 hours, we will have to be patient for another week.

I had been running with the 3.2" before with 0 KR.

I think I should be able to run a 3.2" now with the Gen V, thanks to the porting and polishing and I'm going to prove it.

I don't want to "have to" use the water injection until I go smaller, or bump up the timing,

for extracuricular racing activities.

for extracuricular racing activities. Remember I ran the 3.1" for a solid year back in 05 on 94 octane with no problems and still took home the prize for quickest 1/4 mi run at our Meet.

Bad news, this morning. :( The Fog has left the roads wet

If they don't dry out within the next 3 hours, we will have to be patient for another week.

Thread

Thread Starter

Forum

Replies

Last Post

dbtk2

Performance, Brainstorming & Tuning

13

08-27-2003 11:30 AM