SC Needle Bearing removal procedure

#1

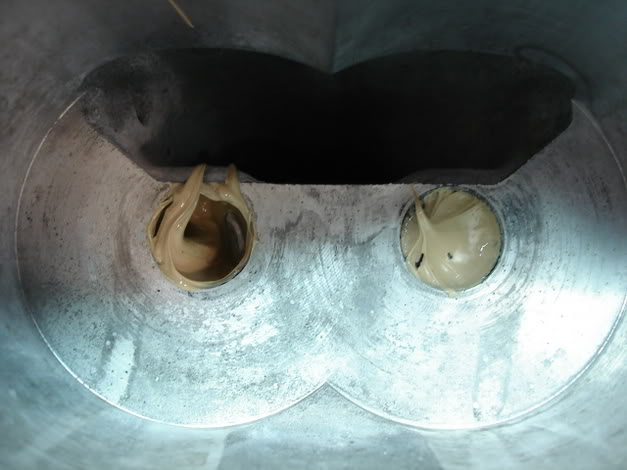

Junior Member

Posts like a Ricer Type-R

Thread Starter

Per request, same procedure applies to all M45, M62, M90, and M112 Eatons:

1. Get these parts. Letter drill "R", 1/8NPT tap, 1/8" brass pipe nipple (threaded

both ends), 1/8" NPT coupler, 1/8NPT grease (zerk) fitting

2. Locate these two holes on the bottom of the Supercharger. Their original

purpose was to preven compression when the original needle bearings were

inserted, to prevent air behind them from compressing and ejecting them:

3. CAREFULLY drill out the hole with the Letter R drill. If you don't have an R, go

to a 11/32" drill (0.343 , slightly larger. Do NOT hit the bearing. Drill straight.

, slightly larger. Do NOT hit the bearing. Drill straight.

If you mar or gall the bearing, it will leave a groove in the bearing pocket of the

SC as it comes out.

4. Carefully tap 1/8" NPT threads into each hole. Use oil. Get them as deep

as you can without hitting the bearing.

5. Results of tapping:

6. After assembling the brass parts and zerk, carefully insert and thread it in

without cross-threading. Get it snug. Use a helper and put a good-quality

grease gun on the fitting:

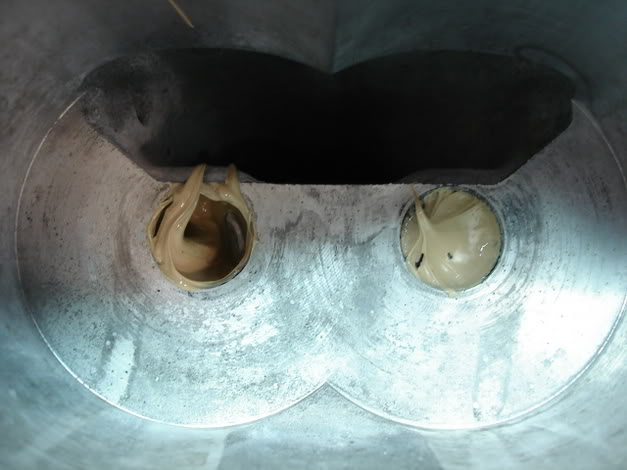

7. Pump away until the bearing comes out. Sometimes they come out with

significant velocity. If your helper is your significant other, and you're horny,

lay a rag inside the SC to 'catch' the bearing. If your helper is anyone else,

aim it in their general direction, and you might get a good show. Of the 4 I've

done, only one came with velocity. The term for the aftermath is 'Gicky'. You

can see the first bearing starting to come out. This one DID have velocity, and

Linda, my trusty helper, got 'Gicky'.

8. The mess you have to clean out (all of it, use solvent) so you don't have a

pre-lubed bearing that wants to move around later:

9. Ready to press new bearings. Press them just below flush (to the same

depth as the original bearing depth):

10. You can get the bearings from www.rollingperformance.com for $20,

pre-greased (this is for a pair). A mighty good deal, considering they typically

ship 2-day express mail for an additional $5.95. Great peace of mind for the

price, and you don't have to buy the expensive grease seperately

I will move these pics to my server sometime soon, then link this post in a

Techinfo article so your grandchildren can learn how to do this.

1. Get these parts. Letter drill "R", 1/8NPT tap, 1/8" brass pipe nipple (threaded

both ends), 1/8" NPT coupler, 1/8NPT grease (zerk) fitting

2. Locate these two holes on the bottom of the Supercharger. Their original

purpose was to preven compression when the original needle bearings were

inserted, to prevent air behind them from compressing and ejecting them:

3. CAREFULLY drill out the hole with the Letter R drill. If you don't have an R, go

to a 11/32" drill (0.343

If you mar or gall the bearing, it will leave a groove in the bearing pocket of the

SC as it comes out.

4. Carefully tap 1/8" NPT threads into each hole. Use oil. Get them as deep

as you can without hitting the bearing.

5. Results of tapping:

6. After assembling the brass parts and zerk, carefully insert and thread it in

without cross-threading. Get it snug. Use a helper and put a good-quality

grease gun on the fitting:

7. Pump away until the bearing comes out. Sometimes they come out with

significant velocity. If your helper is your significant other, and you're horny,

lay a rag inside the SC to 'catch' the bearing. If your helper is anyone else,

aim it in their general direction, and you might get a good show. Of the 4 I've

done, only one came with velocity. The term for the aftermath is 'Gicky'. You

can see the first bearing starting to come out. This one DID have velocity, and

Linda, my trusty helper, got 'Gicky'.

8. The mess you have to clean out (all of it, use solvent) so you don't have a

pre-lubed bearing that wants to move around later:

9. Ready to press new bearings. Press them just below flush (to the same

depth as the original bearing depth):

10. You can get the bearings from www.rollingperformance.com for $20,

pre-greased (this is for a pair). A mighty good deal, considering they typically

ship 2-day express mail for an additional $5.95. Great peace of mind for the

price, and you don't have to buy the expensive grease seperately

I will move these pics to my server sometime soon, then link this post in a

Techinfo article so your grandchildren can learn how to do this.

#3

Junior Member

Posts like a Ricer Type-R

Thread Starter

Billboost was whining.

I'll do a pictorial on the Nosedrive rebuild next. That'll be next week. SC has to be ready for install by a week from today.

I'll do a pictorial on the Nosedrive rebuild next. That'll be next week. SC has to be ready for install by a week from today.

#5

Senior Member

Certified GM nut

Join Date: Sep 2005

Location: Home Sweet Home in New York

Posts: 2,009

Likes: 0

Received 0 Likes

on

0 Posts

Quick Q: You're drilling out those compression holes. Is there any danger to leaving those holes open now that they're wider? Or is it not a problem leaving it that way?

#6

Junior Member

Posts like a Ricer Type-R

Thread Starter

There were holes there before. They serve no purpose during operation, and pose no problems. That area of the SC is not exposed to the outlet area nor bypass. It'* isolated in a 'dead pocket' by the SC outlet gasket.

#7

Senior Member

Certified GM nut

Join Date: Sep 2005

Location: Home Sweet Home in New York

Posts: 2,009

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by willwren

There were holes there before. They serve no purpose during operation, and pose no problems. That area of the SC is not exposed to the outlet area nor bypass. It'* isolated in a 'dead pocket' by the SC outlet gasket.

Nother question: How do you tell when it'* time to replace the bearinngs?

#9

Senior Member

True Car Nut

Join Date: May 2003

Location: Lethbridge, Alberta, _______Canada._______ West Coast Bonneville Fest ___05,06,07 Survivor___

Posts: 8,135

Likes: 0

Received 0 Likes

on

0 Posts

a bearing press basically being a long metal tube thick enough to cover the bearing face so the bearing can be drove home? Or did you use something else. I will do this if i ever have to remove my SC again..

#10

Junior Member

Posts like a Ricer Type-R

Thread Starter

A bearing press being something like this:

http://www.buffalohydraulic.com/prod...ing_press.html

Then use custom stuff (cylindrical bar stock, sockets and extensions, whatever) to fit the bearing to be pressed.

A press like one on that page will be needed for the nosedrive disassembly and rebuild as well.

http://www.buffalohydraulic.com/prod...ing_press.html

Then use custom stuff (cylindrical bar stock, sockets and extensions, whatever) to fit the bearing to be pressed.

A press like one on that page will be needed for the nosedrive disassembly and rebuild as well.