Who's still interested in THIS?

#51

Senior Member

Certified Car Nut

Yes, but where is the room for that. Also, what moves to allow the bar to bend in the middle? The forward facing bars definatly won't hurt, and they will help keep the engine compartment square.

Sidenote: Is that a beer mug second from left in your task bar, Bill?

Sidenote: Is that a beer mug second from left in your task bar, Bill?

#52

Junior Member

Posts like a Ricer Type-R

Thread Starter

Originally Posted by big_news_1

I'm still a little confused about this concept. I understand what you're saying about triangulating the load, but shouldn't the triangles be extended down toward the road instead of forward toward the front bumper? I hope you understand what I'm describing. If you're trying to get rid of upward flex, the added triangulation needs to be on the same plane of movement as the undesired flex. Thus, your support pieces should extend downward. Triangulating on the horizontal plane when the problem is on the vertical plane will not do much to add strength.

Either do that, or get a thicker STB for the stock location.

Either do that, or get a thicker STB for the stock location.

John, that beer mug is the icon for my 3D software. It came that way.

#53

I dont understand the confusion with this idea...It'* a design thats been used for years in many high porformance factory cars(dont ask for an example i cant think of one). And its put into lots of races cars that are built out of factory cars and in one-off race cars.

the point im trying to make is that this is a sound, well tested stabliity item and I would certantly get on as soon as they become avaliable(asuming that the cost isnt astronomical).

I also have a question...will these be made out of steal or aluminum(if its strong enough)

the point im trying to make is that this is a sound, well tested stabliity item and I would certantly get on as soon as they become avaliable(asuming that the cost isnt astronomical).

I also have a question...will these be made out of steal or aluminum(if its strong enough)

#54

Junior Member

Posts like a Ricer Type-R

Thread Starter

Good points, Peter. Exactly why I decided to take this on. You can't argue that successful applications of this idea are all around us every day, including the professional arena (unless your username is feline in nature). These will be steel tubing, same dimentsions as the stock STB. Cost is unknown, but the fabricator works out of his shop at home (nice shop, too), and can produce these for cheaper than most fabricators as he has no overhead. The idea is to produce a BOLT on modification if possible. If not, you may have to have some welding done, but the kit will be as complete as possible. This is NOT the same guy that'* interested in doing porting work for us, but they do know each other.

Rodney is a great welder, and has a home built 4x8 foot CNC plasma cutter capable of cutting 1" steel plate. Making the brackets is simple work. Our priorities:

1. Performance. Has to be worth the cost, must be able to 'feel' it.

2. Cost. Must be affordable.

3. Ease of installation.

4. Cheap/easy shipping. The more compact, the easier and cheaper it is to ship.

One final note about this. I chose this vendor for his particular skills and character. I've known him for years, and he'* a friend, but I wouldn't classify him as a CLOSE friend. I know the quality of his work. There is NO money in this for me whatsoever. I'm just trying to fill a void in some parts for us.

Rodney is a great welder, and has a home built 4x8 foot CNC plasma cutter capable of cutting 1" steel plate. Making the brackets is simple work. Our priorities:

1. Performance. Has to be worth the cost, must be able to 'feel' it.

2. Cost. Must be affordable.

3. Ease of installation.

4. Cheap/easy shipping. The more compact, the easier and cheaper it is to ship.

One final note about this. I chose this vendor for his particular skills and character. I've known him for years, and he'* a friend, but I wouldn't classify him as a CLOSE friend. I know the quality of his work. There is NO money in this for me whatsoever. I'm just trying to fill a void in some parts for us.

#55

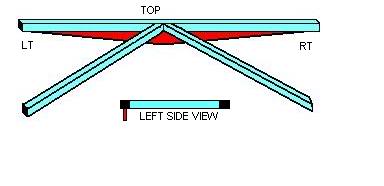

if you were to be at all worred about the bar flexing up and down in the middle like Big_news seems to be worried about could you not add somting like this....(please excuse the crude drawing)

Note; the tapered steel plate(in red) welded on to bottom of the main bar, I would think that somthing like this in 1/4" steel would stop any flexing in the up and down direction.

Note; the tapered steel plate(in red) welded on to bottom of the main bar, I would think that somthing like this in 1/4" steel would stop any flexing in the up and down direction.

#56

Junior Member

Posts like a Ricer Type-R

Thread Starter

#3. Ease of installation.

That would require welding for anyone buying the kit. Simply making the engine bay more rigid may be enough to keep that bar from flexing, even if the 2 added bars are across the corners of the headlights, unattached to the STB. Energy has to go somewhere.

Simply bolting an additional piece of angle iron to the STB would beef it up, but I'd like to tie in the whole front end if possible.

That would require welding for anyone buying the kit. Simply making the engine bay more rigid may be enough to keep that bar from flexing, even if the 2 added bars are across the corners of the headlights, unattached to the STB. Energy has to go somewhere.

Simply bolting an additional piece of angle iron to the STB would beef it up, but I'd like to tie in the whole front end if possible.

#57

ok sorry, i was under the impretion that the whole unit would be fully assembled and welded pryer to shiping.and besides i wasnt worried about flexing...i was just making a sugestion regarding Big_news'* worries thats all

#59

Senior Member

True Car Nut

I'm not personally worried about vertical STB flex, as I'm not modded anywhere near the level of Greenzilla. I was just trying to understand the issue a little better. Peterg22000, your small diagram captured what I was trying to convey. It seems that if you're trying to stop flexing on the vertical plane, you need added strength on the vertical plane as your drawing suggests. Maybe I'm misunderstanding the whole issue, so I'll let it go. I'll still be upgrading once the kit is available, and as long as Bill is confident in his design I'll be satisfied.

Hope it all comes together smoothly... I'll be buying sometime!

Hope it all comes together smoothly... I'll be buying sometime!

#60

Junior Member

Posts like a Ricer Type-R

Thread Starter

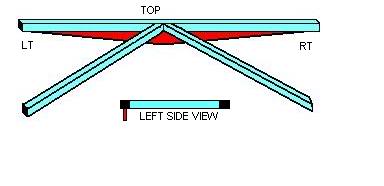

If I can't feel the difference, I won't recommend it. Here'* another example of a brace, but in another direction (this option is still on the table for us):

The only reason I was looking at the STB for the origin is because of the flex I'm seeing. If I can't find a GOOD way to attach there, we'll look at this option.

The only reason I was looking at the STB for the origin is because of the flex I'm seeing. If I can't find a GOOD way to attach there, we'll look at this option.