Swapping series II heads onto EV6/LN3/SI tall deck shortblok

#21

Senior Member

Posts like a Turbo

Thread Starter

Join Date: Jan 2005

Location: Hanoverpark/palatine IL, wrenchin' and cursin'

Posts: 247

Likes: 0

Received 0 Likes

on

0 Posts

Well Got a bunch of pics from the Jyard looks very doable for putting the SII cam in the SI block, got to go back to the Jyard on the 3rd of May with a new puller, I wiped my old one out (dont ask...), only got the SII cam outa the block. the SII victom was a 95 bonnevile SE build date 9/94, 95 model year engine vin K SII NA 3800, gave up a host of secrets....

The SI was from a 90 Pont Bonnevile Vin C LN3 SI NA 3800 (from what I understand, is refered to as the Buick in OZ, the 95 and later SII are refered to as Ecotec) and because the puller broke I had to break the cover off to get to the cam gear and see the snout of the crank, also to pull it, then we started running out of time so I was unable to pull the rockers and pushrods and lifters to pull the cam out (also need to drop the cradle...) so that is what is left for the next run down in may.

I have some interesting things to show...

I will post Pics tomarrow night...gotta work on the 442 on monday

nothing a little work with a lathe and pridgport and some redneck engine-uity couldnt overcome....

James & Al

The SI was from a 90 Pont Bonnevile Vin C LN3 SI NA 3800 (from what I understand, is refered to as the Buick in OZ, the 95 and later SII are refered to as Ecotec) and because the puller broke I had to break the cover off to get to the cam gear and see the snout of the crank, also to pull it, then we started running out of time so I was unable to pull the rockers and pushrods and lifters to pull the cam out (also need to drop the cradle...) so that is what is left for the next run down in may.

I have some interesting things to show...

I will post Pics tomarrow night...gotta work on the 442 on monday

nothing a little work with a lathe and pridgport and some redneck engine-uity couldnt overcome....

James & Al

#22

Senior Member

Posts like a Turbo

Thread Starter

Join Date: Jan 2005

Location: Hanoverpark/palatine IL, wrenchin' and cursin'

Posts: 247

Likes: 0

Received 0 Likes

on

0 Posts

we'll gladly take the SII heads 1.8 and 1.52 intake and exhaust valves over the SI 1.71 and 1.487 dia valves and put them on the SI block (still looking to CC the head chambers for an estimate of how much we can lower comp for the Turbocharger).

you know the SI and SII use the same lifters? oh and the SI and SII do have the same cam journal diameters if it'* a 95 and some 96 SII blocks then the cam bearing part #'* change... to the larger ones....no wonder my manual said that the 97+ have the larger cam bearing journal diameters.

so far it looks like all we have to do is drill and tap two holes in the front of the SI and use the SII cam thrust plate....with a SII T chain set...

custom length pushrods may still be neccisary but research is ongoing, the next trip to the Jyard is May 3rd or so so I can do more measuring/cc'ing

BTW the SII roller rockers are lighter than the L27 roller rockers....

still working on my full writup and pics but this sure looks like it can be done by anyone!

more to come! stay tuned!!!!!

Regards, James

you know the SI and SII use the same lifters? oh and the SI and SII do have the same cam journal diameters if it'* a 95 and some 96 SII blocks then the cam bearing part #'* change... to the larger ones....no wonder my manual said that the 97+ have the larger cam bearing journal diameters.

so far it looks like all we have to do is drill and tap two holes in the front of the SI and use the SII cam thrust plate....with a SII T chain set...

custom length pushrods may still be neccisary but research is ongoing, the next trip to the Jyard is May 3rd or so so I can do more measuring/cc'ing

BTW the SII roller rockers are lighter than the L27 roller rockers....

still working on my full writup and pics but this sure looks like it can be done by anyone!

more to come! stay tuned!!!!!

Regards, James

#23

Senior Member

Certified GM nut

Join Date: Feb 2003

Location: Georgia

Posts: 2,095

Likes: 0

Received 0 Likes

on

0 Posts

Wow, looks like a pretty wild project I hope it works out. I'd love to see a SI with SII parts in it. I'm glad there are crazy people out there like you willing to try stuff like this just for the hell of it.

My only thing is I can't imagine this being a project for "anyone." Between the cost of all the parts necessary including a custom exhaust (putting it under the HOOD of a Bonneville that is ), the need to drill holes in the SI, and all the other headaches necessary for a nominal HP gain...just doesn't seem to pass the practicality test.

), the need to drill holes in the SI, and all the other headaches necessary for a nominal HP gain...just doesn't seem to pass the practicality test.

VERY neat work anyway!

My only thing is I can't imagine this being a project for "anyone." Between the cost of all the parts necessary including a custom exhaust (putting it under the HOOD of a Bonneville that is

VERY neat work anyway!

#24

Senior Member

Posts like a Turbo

Thread Starter

Join Date: Jan 2005

Location: Hanoverpark/palatine IL, wrenchin' and cursin'

Posts: 247

Likes: 0

Received 0 Likes

on

0 Posts

ah but you realize that since this is possible it will only be a matter of time before someone bolts an L67 blower (gen V would be possible also) with the SII upper end and with the static compression lowered you can run more boost...SI guys can say goodbye to the M62.....HELLO M90!!!!

I am already up to two pages of info on the writup and I have less than 50% left

Here is a pic of the SII cam gear, balance shaft gear, and the thrust plate, from left to right. the balbance shaft gears are identical betweem the SI and SII tooth pattern wise so you can still keep your SI balance shaft and the SII cam gears will mesh perfectly. the thrust plate on the far right is the part that will have to be centered over the cam hole and the two small torx flush head screw holes will need to be centerpunched, drilled ~5/16 of an inch deep and tapped for the thread of the bolts...this looks like the hardest part of the whole swap.

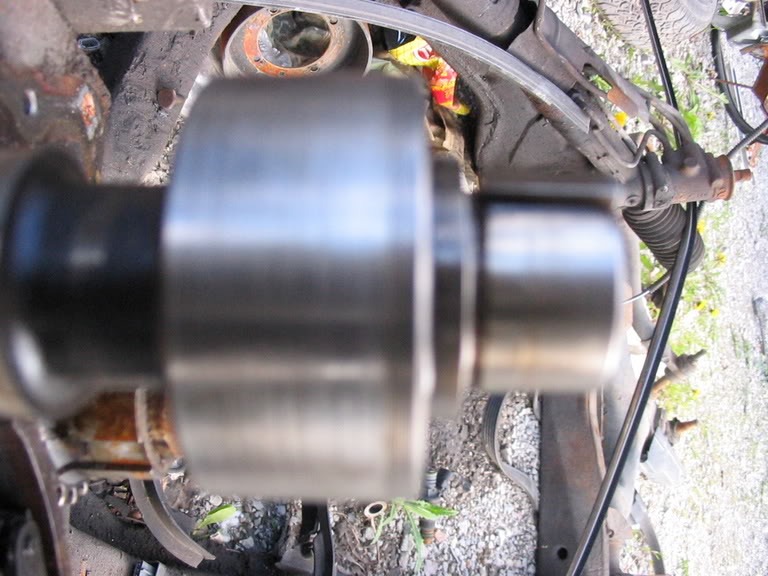

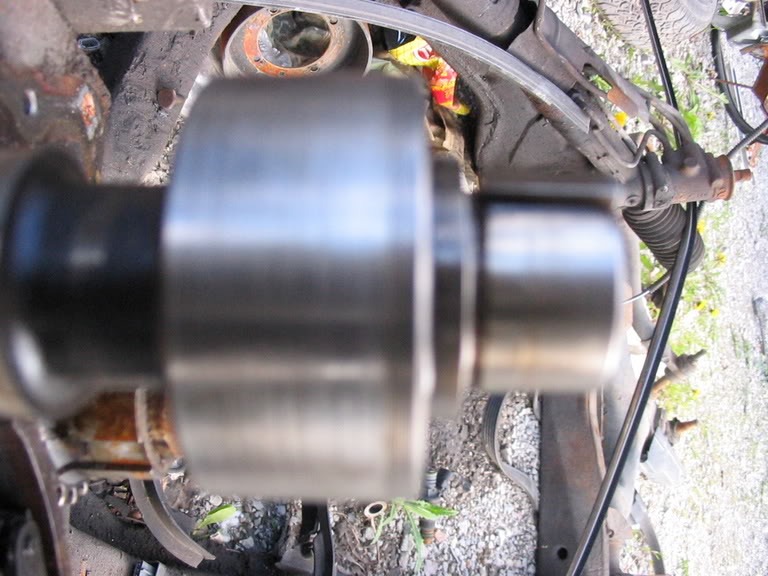

but I still have some measuring to do in the Jyard I have to compare the SI crank sprocket (timing chain) to the SII one and make sure that both have the same oil pump drive splines, as in this picture of the SII crank sprocket which has the same crank snout diam as the SI. however you cannot use the SI crank sprocket with SII cam sprocket and or chain because of the differences in the tooth pitch of the SI and SII timing chains.

more to come stay tuned!

Regards, James & AL

I am already up to two pages of info on the writup and I have less than 50% left

Here is a pic of the SII cam gear, balance shaft gear, and the thrust plate, from left to right. the balbance shaft gears are identical betweem the SI and SII tooth pattern wise so you can still keep your SI balance shaft and the SII cam gears will mesh perfectly. the thrust plate on the far right is the part that will have to be centered over the cam hole and the two small torx flush head screw holes will need to be centerpunched, drilled ~5/16 of an inch deep and tapped for the thread of the bolts...this looks like the hardest part of the whole swap.

but I still have some measuring to do in the Jyard I have to compare the SI crank sprocket (timing chain) to the SII one and make sure that both have the same oil pump drive splines, as in this picture of the SII crank sprocket which has the same crank snout diam as the SI. however you cannot use the SI crank sprocket with SII cam sprocket and or chain because of the differences in the tooth pitch of the SI and SII timing chains.

more to come stay tuned!

Regards, James & AL

#27

Senior Member

True Car Nut

Join Date: Feb 2003

Location: Philly

Posts: 4,508

Likes: 0

Received 0 Likes

on

0 Posts

It may be impractical and expensive for most people but i'm sure its fun as he|| for these guys. It dosen't sound like too much money is going into this particular project esp. since all the fabrication is being done by them.

Keep the updates comming. This is exciting.

Keep the updates comming. This is exciting.

#28

Senior Member

Posts like a Turbo

Thread Starter

Join Date: Jan 2005

Location: Hanoverpark/palatine IL, wrenchin' and cursin'

Posts: 247

Likes: 0

Received 0 Likes

on

0 Posts

OK fer the fellow psychotic gearheads out there....

The rear 90 3800 LN3 Vin C engine in our twin engine 94 Olds Cutlass 442 will be getting Turbocharged this winter and get a Mega Squirt EFI setup (90 non PCM controlled trans) and we have already swapped to the Delco ignition, there are plans for an intercooler to be plumbed into the mix to feed a TB located on the belt side of the engine for better plumbing.

One of my goals is to swap the SII cam, heads, intake onto the SI 3800, and have the specific modifications required to make this Hybrid, available to anyone else who might be interested in getting more power from their SI 3800.

All references to SI are taken from a 90 Vin C 3800 and all SII are in reference to a 95 Vin K 3800 engine, these may also correlate to other SI and SII engine years.

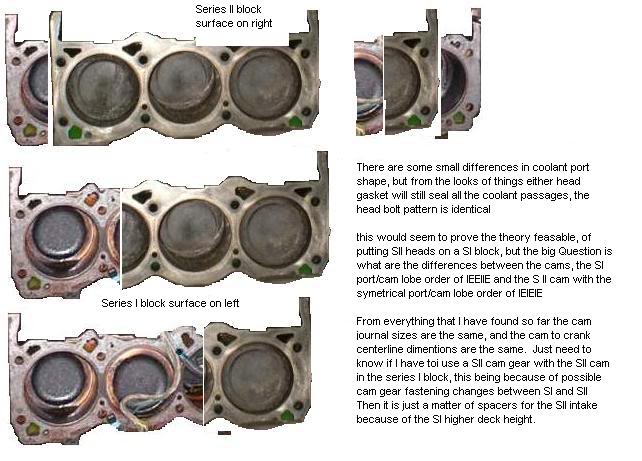

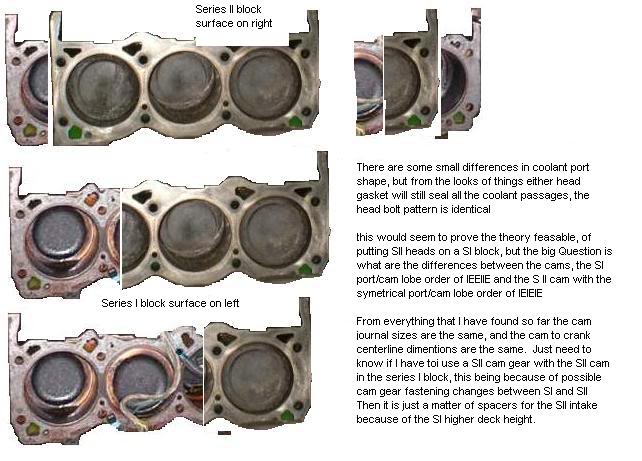

SI & SII 3800 differences/similarities: They seem to have the same bolt pattern on the ends of the heads, but different accessory mounts, this would allow the use of the SI accessory’* and belt drive with the SII heads. The 90 LN3 block (all SI) has a taller deck height which with using the series II Lower intake manifold will require spacers with the SII heads on the SI block. The different looking coolant bosses from the block into the heads is not a big deal, the head gaskets will still seal them... at least the SII V6 isn’t reverse flow and have the massive differences like the Gen I (regular) small block Chevy V8 vs. LT1/LS1 Gen II/III V8’* though more than a couple of people have put LT1 heads on the Gen I SBC with just a couple of modifications. Here is a side by side comparison of the SI and SII block surfaces.

The camshaft lifters are hydraulic roller for both engines but the series II has shorter pushrods for its lower deck height, there is a possibility the stock LN3 pushrods will work with the SII heads, but custom length pushrods are not expensive, if they are required. The valve arrangement is different between the SI and SII, i.e. the cam lobe timing events are tailored for the I-E-I-E-I-E valve positions of the SII and not the E-I-I-E-I-E of the LN3, this is one of the only things that I have found different between the cams. The other major change concerns the balance shaft bearings, the sleeve bearings (SII) that got changed from roller bearings (SI) on the balance shaft. The SI & SII cams have identical bearing journal spacing as well as the lobes, so they would line up correctly with the lifter bores. In one manual I found that there are differences in the SI and SII bearing journal diameters, but it also states that it is 97 and later SII that has the larger diameter, whether or not this is the case still remains to be seen.

Series I:

Camshaft Journal Diameter = 1.785-1.786 in

Bearing-to-Journal Clearance = 0.0005-0.0025 in

Series II:

Journal Diameter = 1.8462-1.8448 in

Bearing-to-Journal Clearance = 0.0016-0.0047 in

If this is the case, then it would require the early SII cam to slide into the SI cam bearings or the later SII cam would have to be chucked in a Lathe and cut the journals down and polish them to the correct diameter for proper bearing clearances. The other difference between the SI & SII cams is the snout and timing chain differences. The SI cam (in the 2 SI blocks I have looked at) uses a flange on the front of the cam to keep it from walking back in the block and uses a cam button on a spring to keep it from walking forward into the T chain cover. This pic is of a non balance shaft equipped SI.

The SII cam however (has no front flange and can slid back and forth no problem) slips into the block and has a flat retainer/thrust plate that bolts on with two flush head torx bolts, this keeps the cam from being able to walk forward in the block.

Then after the plate the balance shaft gear slips over the snout of the cam with the cam Timing chain gear going on right after and tightened with a single bolt, and with the Thrust plate behind the balance shaft gear/T chain gear this prevents the cam from walking backward in the block. And yes the SI and SII do have the same cam journal diameters if it'* a 95 (and some/all 96?) SII blocks then the cam bearing part #'* change... to the larger ones....no wonder my manual said that the 97+ have the larger cam bearing journal diameters-and this is also shown by the 95 and 96 SII blocks using the same part # cam bearings as the SI blocks. The Cam specs are as follows for a 90 Vin C 3800 duration at .050 is 188 deg on the intake and 191 deg on the exhaust with the lobe separation angle of 114 degrees (no valve lift #’* found-yet). The 95 Vin K SII cam specs out at 180 deg intake and 191 degrees on the exhaust at .050, and the lobe separation of 115 degree’*, the SII cam also lists valve lift at .411/.408, on the intake/exhaust valves respectively.

The other difference that I can see is that the pushrods will have more of a tilt to them than the SI pushrods when the SII heads are placed on the SI block but this shouldn’t be a problem as plenty of engines have been designed with pushrods that are not directly in line with the axis of the lifter bore, the only side effect would be a little more thrust loading on the lifter to bore surface. Did you know the SI and SII use the same lifters? Same part #’*! The pushrods on the SI are 7.965 inches in overall length where the SII pushrods are 6.959 inches in length. This would seem to indicate that the shorter deck height is approx 1 inch on the SII block (presumably for a smaller engine package that will fit into smaller engine bays) but I have yet to verify this through specs or through measurements. This hybrid engine may still require custom length pushrods for proper lifter preload and valvetrain geometry

The SII exhaust manifolds would have to be used with the SII heads, however it seems possible that the SI tubular log manifolds can be cut and modified to fit the SII head, however with the plethora of aftermarket SII headers this wouldn’t be necessary, though the X-over pipe would be a little longer due to the SI blocks taller deck height. Here are pics of the SII front (cast) and rear (tube steel) exhaust manifolds.

SI front manifold made of tubular steel

The pistons in the SI are listed as having two 1.5 mm and one 3 mm ring grooves with a 1.377 compression height rated at 8.5 to 1 Compression ratio with a dish of .260 inch deep x 3.050 inches in diameter. The SII pistons spec out as having, one 1.2 mm, one 1.5 mm, and one 2 mm ring grooves, with a 1.090 inch compression height and having a dish of .050 inch deep x 2.9 inch diameter.

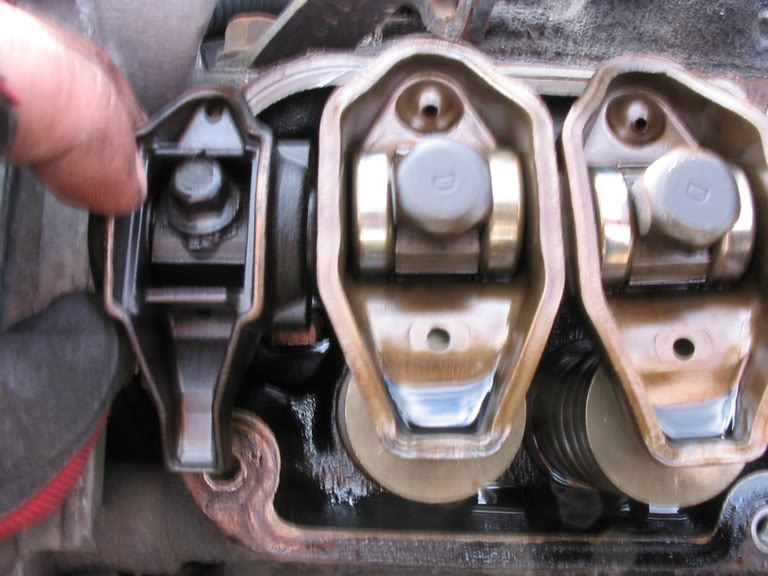

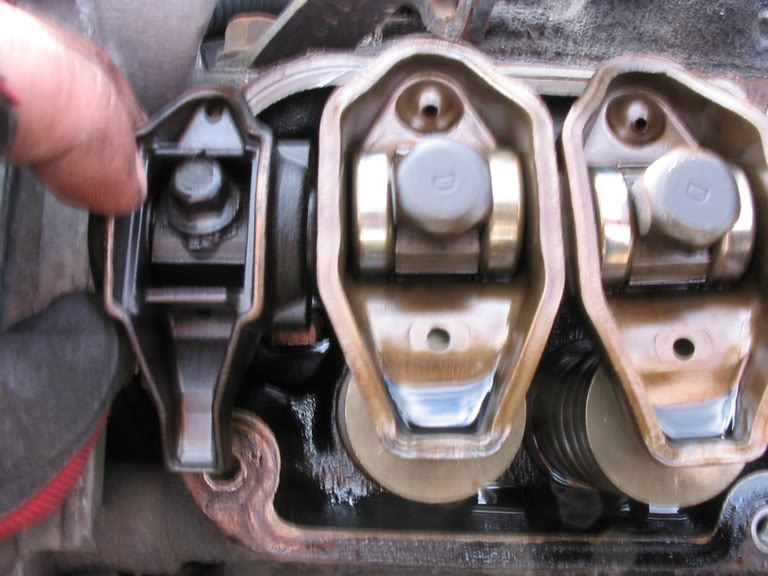

Now for the cylinder heads, the primary difference between the SI and SII heads are the intake and exhaust valve and port locations/order, with the SI head having a EIIEIE arrangement and the SII having a “symmetrical port” design of IEIEIE, these differences are why the Camshaft from the SII must be used as it has the correct lobe phasing/order. Now besides the fact that the SII heads have much better engineering of the port design and excellent crossectional area/flow the SII heads feature 1.8 and 1.52 inch intake and exhaust valves, and they measure 4.7212/4.7133 inches overall length on the intake and exhaust respectively. While the SI heads have 1.71 and 1.487 inch diameter intake and exhaust valves, and measure 4.727 inches overall length each. I have yet to determine the SI and SII combustion chamber volume but the differences in the dishes of the pistons would lead me to believe that there is a possibility that the SII heads have a slightly larger chamber than the SI heads, but this has yet to be verified by me. Also the SII roller rockers are lighter than the L27 roller rockers, just by handling them. From the look of things I can make the roller rockers a different ratio with the Bridgeport and a 300 amp TIG welder, here is a side by side pic of the SII and the SI rockers.

From the looks of things the Timing chain from the SII will work with the SI block as they use the same chain tensioner part # between the SI and SII setup, however you cannot use the SI chain with the SII cam gear because the spacing (pitch) of the teeth are different and will not work. This should not pose a problem since the SII timing chain crank sprocket will fit on the SI crank snout; however one of the things I have to check is whether the splines on it are the same as the SI splines that drive the oil pump that is in the Timing chain cover, but I would think that they wouldn’t have changed, and if they did then you would also require the SII sun gear (and maybe the ring gear) of the gerotor type oil pump.

I think that covers most of the differences and/or similarities.

Now for what I am trying to accomplish with this Hybrid project on our 90 Vin C 3800 in the rear of the twin engine Olds 442:

I am looking to swap the SII L67 heads with the injector bosses in the heads (this means that yes, you can put a L67 supercharged top end onto a SI block-with the L67 intake- SI guys can say goodbye to the M62.....HELLO M90!) with a modified factory fuel rail. Along with the L36 NA lower intake manifold (with spacers…) with it’* 6 injector bosses and modified factory fuel rails, so that we can run 12 30lb hr injectors at 50 psi with a boost referenced pressure regulator (Quad 4 injectors-free from J yards….) with the Mega Squirt DIY EFI system controlling them with custom fuel tables for the Mitsubishi TD06-17c-8cm^2 Turbocharger from a 4.3L Cyclone/Typhoon, this Turbocharger is capable of enough flow to support 400Hp which would require ~ 60 lb hr injector per cylinder, it’* much cheaper for us to use two 30 lb hr injectors. The L36 NA lower intake would receive bell mouthing of the intake runners, and we would Fabricate a sheet metal aluminum Upper intake plenum that would have a N* or LS1 TB located on the belt drive side of the engine to allow for better plumbing of the Turbocharger to Intercooler to TB ductwork without any flow robbing bends. There is no big deal with this as our rear engine has crank, WP, alt, and tensioner only and wouldn’t interfere with the TB. Mega Squirt EFI will work with MAF or MAP based EFI setups but I think we will go with a 3 bar MAP sensor and use speed density tables and forgo the LS1 MAF etc and its associated cost, though it’* not out of the question. The SII exhaust manifolds will be used with the rear manifolds normal outlet removed and the crossover pipe that is (now) too short will be cut in half to facilitate the fabrication of the Turbocharger mount/flange.

Besides the benefits of factory SII parts on the SI block you can then use the aftermarket SII performance parts, an IC under a L67 supercharger etc you name it…the possibilities would be endless, at least it’* possible.

Modifications required:

Here is a pic of the SII cam gear, balance shaft gear, and the thrust plate, from left to right. The balance shaft gears are identical between the SI and SII tooth pattern wise so you can still keep your SI balance shaft and the SII cam gears will mesh perfectly. Here is a pick of the SI and SII balance shaft gears-identical

The thrust plate on the far right is the part that will have to be centered over the cam hole and the two small torx flush head screw holes will need to be center punched, drilled ~5/16 of an inch deep and tapped for the thread of the bolts...this looks like the hardest part of the whole swap.

But I still have some measuring to do in the Junkyard I have to compare the SI crank sprocket (timing chain) to the SII one and make sure that both have the same oil pump drive splines, as in this picture of the SII crank sprocket which has the same crank snout diameter as the SI. However you cannot use the SI crank sprocket with SII cam sprocket and or chain because of the differences in the tooth pitch of the SI and SII timing chains.

So far it looks like all we have to do is drill and tap two holes in the front of the SI and use the SII cam thrust plate....with a SII T chain set... here you can see the difference between the SII and SI cam gear tooth pitch, the SII gear is on the top.

Now, bolting the Lower L36 or L67 intake on the hybrid, as the intake bolts are perpendicular to the intake port surfaces all that you need are longer bolts to account for the spacers thickness. The Spacers can be cut from Aluminum stock of the correct thickness with a plasma cutter and milled with the correct size coolant and intake port patterns with the intake bolt holes drilled into it, this is also an easy task as I have access to a Bridgeport mill and alum stock of varying thicknesses. Then the spacers need to be bolted to the intake and a few more small holes drilled and the spacer needs to be countersunk for flush head screws to hold the spacers to the Intake with just a paper gasket material between them then tap the small holes for the correct thread that your flush head bolts have and bolt the spacers to the intake. Then you would just use the factory SII intake gaskets between the intake (and its spacers) and the heads, and fasten it down with the longer intake bolts. The spacers would be cut to the same shape etc as the intake port flange such as the L36 Lower intake in this pic of the Lower intake with the intake gasket on it, you could basically copy the intake gasket.

You may be able to use the stock SI pushrods if they will work but if not a pair of adjustable checking pushrods can be used to determine the correct length and purchase new custom length pushrods from Manley/Comp Cams etc. A pair of checking pushrods is 25$ and a set of high end custom pushrods goes for 80-100$ for a V8 and you don’t need that many except for maybe spares…

The Upper intake (L36) or supercharger (L67) would bolt right onto the Lower intake with no changes however the supercharged fuel rail will need to be fit for the wider head spacing of the taller block. And the belt routing will need some work but would seem to be a possibility that it would work with a SI or SII accessory/belt system no problem, but as I am not attempting this I cannot say for sure…

Why the hell am I doing this instead of swapping in an L67:

Lowbuck Redneck Modern Hotrodding! We is Rednecks, we is cheap! We already have the 3800 SI drive train in the rear of the 442 and since we are going to be Turbocharging it we will be running MS EFI, as the trans isn’t computer controlled the MS system will work so we don’t have to spend tons of $$ to get a custom PCM/ECM, and because I can tune the MS to run it just fine-even with 12 injectors using peak and hold drivers for the low impedance Quad4 injectors. It is well worth spending a day at the J yard tearing down a couple engines to check/compare dimensions and feasibility of the swap. I have the time and the energy as well as the tools to try this out for nothing, it will just be a little investment of time, if it doesn’t work because of massive cam differences (doesn’t seem likely...) at least someone will have taken time to prove it'* not possible and document the proceedings. But like Gearheads of old who put a blower from a diesel on their V8’* or swapped Flathead fords into T bucket roadsters, blazing new trails, I am doing it for the fun and challenge, and of course to go faster!

.

We are trying this because for the price of a set of SI roller rockers we can put the SII heads with factory roller rockers, and it'* better flowing ports and larger valves, and the lower NA intake on with machined spacers, and fabricate an upper plenum that would allow use of a N* TB or equivalent. Along with the SII exhaust manifolds and fabricate the crossover for the turbo flange, ourselves saving $, who can argue with that?

You can do anything with a Plasma cutter, welder, Bridgeport mill, and lathe…

Case in point…Twin engine 94 Olds Cutlass 442 New Pic of the rear engine…

More to come…stay tuned….

Regards, James

The rear 90 3800 LN3 Vin C engine in our twin engine 94 Olds Cutlass 442 will be getting Turbocharged this winter and get a Mega Squirt EFI setup (90 non PCM controlled trans) and we have already swapped to the Delco ignition, there are plans for an intercooler to be plumbed into the mix to feed a TB located on the belt side of the engine for better plumbing.

One of my goals is to swap the SII cam, heads, intake onto the SI 3800, and have the specific modifications required to make this Hybrid, available to anyone else who might be interested in getting more power from their SI 3800.

All references to SI are taken from a 90 Vin C 3800 and all SII are in reference to a 95 Vin K 3800 engine, these may also correlate to other SI and SII engine years.

SI & SII 3800 differences/similarities: They seem to have the same bolt pattern on the ends of the heads, but different accessory mounts, this would allow the use of the SI accessory’* and belt drive with the SII heads. The 90 LN3 block (all SI) has a taller deck height which with using the series II Lower intake manifold will require spacers with the SII heads on the SI block. The different looking coolant bosses from the block into the heads is not a big deal, the head gaskets will still seal them... at least the SII V6 isn’t reverse flow and have the massive differences like the Gen I (regular) small block Chevy V8 vs. LT1/LS1 Gen II/III V8’* though more than a couple of people have put LT1 heads on the Gen I SBC with just a couple of modifications. Here is a side by side comparison of the SI and SII block surfaces.

The camshaft lifters are hydraulic roller for both engines but the series II has shorter pushrods for its lower deck height, there is a possibility the stock LN3 pushrods will work with the SII heads, but custom length pushrods are not expensive, if they are required. The valve arrangement is different between the SI and SII, i.e. the cam lobe timing events are tailored for the I-E-I-E-I-E valve positions of the SII and not the E-I-I-E-I-E of the LN3, this is one of the only things that I have found different between the cams. The other major change concerns the balance shaft bearings, the sleeve bearings (SII) that got changed from roller bearings (SI) on the balance shaft. The SI & SII cams have identical bearing journal spacing as well as the lobes, so they would line up correctly with the lifter bores. In one manual I found that there are differences in the SI and SII bearing journal diameters, but it also states that it is 97 and later SII that has the larger diameter, whether or not this is the case still remains to be seen.

Series I:

Camshaft Journal Diameter = 1.785-1.786 in

Bearing-to-Journal Clearance = 0.0005-0.0025 in

Series II:

Journal Diameter = 1.8462-1.8448 in

Bearing-to-Journal Clearance = 0.0016-0.0047 in

If this is the case, then it would require the early SII cam to slide into the SI cam bearings or the later SII cam would have to be chucked in a Lathe and cut the journals down and polish them to the correct diameter for proper bearing clearances. The other difference between the SI & SII cams is the snout and timing chain differences. The SI cam (in the 2 SI blocks I have looked at) uses a flange on the front of the cam to keep it from walking back in the block and uses a cam button on a spring to keep it from walking forward into the T chain cover. This pic is of a non balance shaft equipped SI.

The SII cam however (has no front flange and can slid back and forth no problem) slips into the block and has a flat retainer/thrust plate that bolts on with two flush head torx bolts, this keeps the cam from being able to walk forward in the block.

Then after the plate the balance shaft gear slips over the snout of the cam with the cam Timing chain gear going on right after and tightened with a single bolt, and with the Thrust plate behind the balance shaft gear/T chain gear this prevents the cam from walking backward in the block. And yes the SI and SII do have the same cam journal diameters if it'* a 95 (and some/all 96?) SII blocks then the cam bearing part #'* change... to the larger ones....no wonder my manual said that the 97+ have the larger cam bearing journal diameters-and this is also shown by the 95 and 96 SII blocks using the same part # cam bearings as the SI blocks. The Cam specs are as follows for a 90 Vin C 3800 duration at .050 is 188 deg on the intake and 191 deg on the exhaust with the lobe separation angle of 114 degrees (no valve lift #’* found-yet). The 95 Vin K SII cam specs out at 180 deg intake and 191 degrees on the exhaust at .050, and the lobe separation of 115 degree’*, the SII cam also lists valve lift at .411/.408, on the intake/exhaust valves respectively.

The other difference that I can see is that the pushrods will have more of a tilt to them than the SI pushrods when the SII heads are placed on the SI block but this shouldn’t be a problem as plenty of engines have been designed with pushrods that are not directly in line with the axis of the lifter bore, the only side effect would be a little more thrust loading on the lifter to bore surface. Did you know the SI and SII use the same lifters? Same part #’*! The pushrods on the SI are 7.965 inches in overall length where the SII pushrods are 6.959 inches in length. This would seem to indicate that the shorter deck height is approx 1 inch on the SII block (presumably for a smaller engine package that will fit into smaller engine bays) but I have yet to verify this through specs or through measurements. This hybrid engine may still require custom length pushrods for proper lifter preload and valvetrain geometry

The SII exhaust manifolds would have to be used with the SII heads, however it seems possible that the SI tubular log manifolds can be cut and modified to fit the SII head, however with the plethora of aftermarket SII headers this wouldn’t be necessary, though the X-over pipe would be a little longer due to the SI blocks taller deck height. Here are pics of the SII front (cast) and rear (tube steel) exhaust manifolds.

SI front manifold made of tubular steel

The pistons in the SI are listed as having two 1.5 mm and one 3 mm ring grooves with a 1.377 compression height rated at 8.5 to 1 Compression ratio with a dish of .260 inch deep x 3.050 inches in diameter. The SII pistons spec out as having, one 1.2 mm, one 1.5 mm, and one 2 mm ring grooves, with a 1.090 inch compression height and having a dish of .050 inch deep x 2.9 inch diameter.

Now for the cylinder heads, the primary difference between the SI and SII heads are the intake and exhaust valve and port locations/order, with the SI head having a EIIEIE arrangement and the SII having a “symmetrical port” design of IEIEIE, these differences are why the Camshaft from the SII must be used as it has the correct lobe phasing/order. Now besides the fact that the SII heads have much better engineering of the port design and excellent crossectional area/flow the SII heads feature 1.8 and 1.52 inch intake and exhaust valves, and they measure 4.7212/4.7133 inches overall length on the intake and exhaust respectively. While the SI heads have 1.71 and 1.487 inch diameter intake and exhaust valves, and measure 4.727 inches overall length each. I have yet to determine the SI and SII combustion chamber volume but the differences in the dishes of the pistons would lead me to believe that there is a possibility that the SII heads have a slightly larger chamber than the SI heads, but this has yet to be verified by me. Also the SII roller rockers are lighter than the L27 roller rockers, just by handling them. From the look of things I can make the roller rockers a different ratio with the Bridgeport and a 300 amp TIG welder, here is a side by side pic of the SII and the SI rockers.

From the looks of things the Timing chain from the SII will work with the SI block as they use the same chain tensioner part # between the SI and SII setup, however you cannot use the SI chain with the SII cam gear because the spacing (pitch) of the teeth are different and will not work. This should not pose a problem since the SII timing chain crank sprocket will fit on the SI crank snout; however one of the things I have to check is whether the splines on it are the same as the SI splines that drive the oil pump that is in the Timing chain cover, but I would think that they wouldn’t have changed, and if they did then you would also require the SII sun gear (and maybe the ring gear) of the gerotor type oil pump.

I think that covers most of the differences and/or similarities.

Now for what I am trying to accomplish with this Hybrid project on our 90 Vin C 3800 in the rear of the twin engine Olds 442:

I am looking to swap the SII L67 heads with the injector bosses in the heads (this means that yes, you can put a L67 supercharged top end onto a SI block-with the L67 intake- SI guys can say goodbye to the M62.....HELLO M90!) with a modified factory fuel rail. Along with the L36 NA lower intake manifold (with spacers…) with it’* 6 injector bosses and modified factory fuel rails, so that we can run 12 30lb hr injectors at 50 psi with a boost referenced pressure regulator (Quad 4 injectors-free from J yards….) with the Mega Squirt DIY EFI system controlling them with custom fuel tables for the Mitsubishi TD06-17c-8cm^2 Turbocharger from a 4.3L Cyclone/Typhoon, this Turbocharger is capable of enough flow to support 400Hp which would require ~ 60 lb hr injector per cylinder, it’* much cheaper for us to use two 30 lb hr injectors. The L36 NA lower intake would receive bell mouthing of the intake runners, and we would Fabricate a sheet metal aluminum Upper intake plenum that would have a N* or LS1 TB located on the belt drive side of the engine to allow for better plumbing of the Turbocharger to Intercooler to TB ductwork without any flow robbing bends. There is no big deal with this as our rear engine has crank, WP, alt, and tensioner only and wouldn’t interfere with the TB. Mega Squirt EFI will work with MAF or MAP based EFI setups but I think we will go with a 3 bar MAP sensor and use speed density tables and forgo the LS1 MAF etc and its associated cost, though it’* not out of the question. The SII exhaust manifolds will be used with the rear manifolds normal outlet removed and the crossover pipe that is (now) too short will be cut in half to facilitate the fabrication of the Turbocharger mount/flange.

Besides the benefits of factory SII parts on the SI block you can then use the aftermarket SII performance parts, an IC under a L67 supercharger etc you name it…the possibilities would be endless, at least it’* possible.

Modifications required:

Here is a pic of the SII cam gear, balance shaft gear, and the thrust plate, from left to right. The balance shaft gears are identical between the SI and SII tooth pattern wise so you can still keep your SI balance shaft and the SII cam gears will mesh perfectly. Here is a pick of the SI and SII balance shaft gears-identical

The thrust plate on the far right is the part that will have to be centered over the cam hole and the two small torx flush head screw holes will need to be center punched, drilled ~5/16 of an inch deep and tapped for the thread of the bolts...this looks like the hardest part of the whole swap.

But I still have some measuring to do in the Junkyard I have to compare the SI crank sprocket (timing chain) to the SII one and make sure that both have the same oil pump drive splines, as in this picture of the SII crank sprocket which has the same crank snout diameter as the SI. However you cannot use the SI crank sprocket with SII cam sprocket and or chain because of the differences in the tooth pitch of the SI and SII timing chains.

So far it looks like all we have to do is drill and tap two holes in the front of the SI and use the SII cam thrust plate....with a SII T chain set... here you can see the difference between the SII and SI cam gear tooth pitch, the SII gear is on the top.

Now, bolting the Lower L36 or L67 intake on the hybrid, as the intake bolts are perpendicular to the intake port surfaces all that you need are longer bolts to account for the spacers thickness. The Spacers can be cut from Aluminum stock of the correct thickness with a plasma cutter and milled with the correct size coolant and intake port patterns with the intake bolt holes drilled into it, this is also an easy task as I have access to a Bridgeport mill and alum stock of varying thicknesses. Then the spacers need to be bolted to the intake and a few more small holes drilled and the spacer needs to be countersunk for flush head screws to hold the spacers to the Intake with just a paper gasket material between them then tap the small holes for the correct thread that your flush head bolts have and bolt the spacers to the intake. Then you would just use the factory SII intake gaskets between the intake (and its spacers) and the heads, and fasten it down with the longer intake bolts. The spacers would be cut to the same shape etc as the intake port flange such as the L36 Lower intake in this pic of the Lower intake with the intake gasket on it, you could basically copy the intake gasket.

You may be able to use the stock SI pushrods if they will work but if not a pair of adjustable checking pushrods can be used to determine the correct length and purchase new custom length pushrods from Manley/Comp Cams etc. A pair of checking pushrods is 25$ and a set of high end custom pushrods goes for 80-100$ for a V8 and you don’t need that many except for maybe spares…

The Upper intake (L36) or supercharger (L67) would bolt right onto the Lower intake with no changes however the supercharged fuel rail will need to be fit for the wider head spacing of the taller block. And the belt routing will need some work but would seem to be a possibility that it would work with a SI or SII accessory/belt system no problem, but as I am not attempting this I cannot say for sure…

Why the hell am I doing this instead of swapping in an L67:

Lowbuck Redneck Modern Hotrodding! We is Rednecks, we is cheap! We already have the 3800 SI drive train in the rear of the 442 and since we are going to be Turbocharging it we will be running MS EFI, as the trans isn’t computer controlled the MS system will work so we don’t have to spend tons of $$ to get a custom PCM/ECM, and because I can tune the MS to run it just fine-even with 12 injectors using peak and hold drivers for the low impedance Quad4 injectors. It is well worth spending a day at the J yard tearing down a couple engines to check/compare dimensions and feasibility of the swap. I have the time and the energy as well as the tools to try this out for nothing, it will just be a little investment of time, if it doesn’t work because of massive cam differences (doesn’t seem likely...) at least someone will have taken time to prove it'* not possible and document the proceedings. But like Gearheads of old who put a blower from a diesel on their V8’* or swapped Flathead fords into T bucket roadsters, blazing new trails, I am doing it for the fun and challenge, and of course to go faster!

.

We are trying this because for the price of a set of SI roller rockers we can put the SII heads with factory roller rockers, and it'* better flowing ports and larger valves, and the lower NA intake on with machined spacers, and fabricate an upper plenum that would allow use of a N* TB or equivalent. Along with the SII exhaust manifolds and fabricate the crossover for the turbo flange, ourselves saving $, who can argue with that?

You can do anything with a Plasma cutter, welder, Bridgeport mill, and lathe…

Case in point…Twin engine 94 Olds Cutlass 442 New Pic of the rear engine…

More to come…stay tuned….

Regards, James

#29

Junior Member

Posts like a Ricer Type-R

James, looks like good info, alot of work, but not out of the realm of possiblities for the guy with the right tools and ALOT of time. I don't argue that you're having a blast doing this, but 99% of the guys out there will just talk about doing this, but end up trading in or swapping instead.

For the record, your 90 isn't a Series1. That'* going to cause alot of confusion here. Series 1 started in 1992 with the L27. The 90 is a PRE-Series1 if you want to call it something.

For the record, your 90 isn't a Series1. That'* going to cause alot of confusion here. Series 1 started in 1992 with the L27. The 90 is a PRE-Series1 if you want to call it something.

#30

Senior Member

Posts like a Corvette

Join Date: Jul 2004

Location: Winnipeg, Manitoba, Canada

Posts: 1,445

Likes: 0

Received 0 Likes

on

0 Posts

I got a little confused as well. Just call it the LN3 (pre Series 1 3800, 88-91)

Sounds like you are going to have a blast. It is quite the undertaking, I hope it all works out great.

Sounds like you are going to have a blast. It is quite the undertaking, I hope it all works out great.