Shielded EGR Stovepipe

#1

Senior Member

True Car Nut

Thread Starter

Bob Dillon'* latest topic regarding pipes and sleeves got me to thinking about different options available for folks to remedy the UIM problem. This reply to Bob became so off-topic that I just moved it to a new topic rather than risk arrest and incarceration for extreme hijacking. This is what happens when old folks stay up past their bedtime!

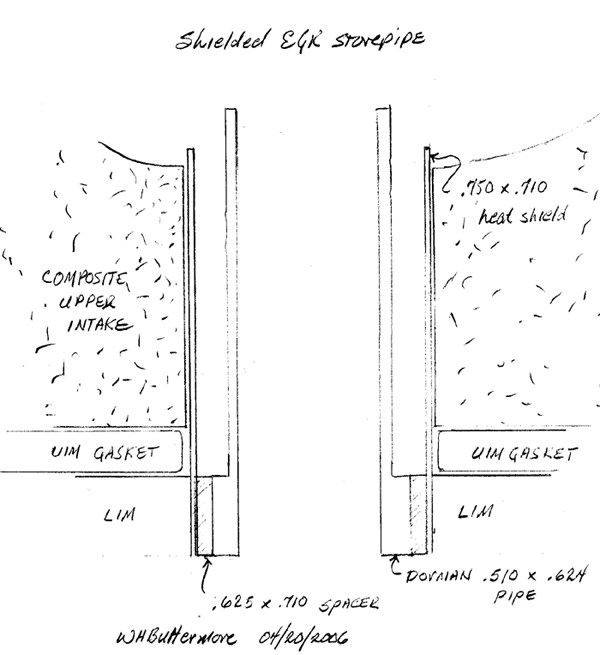

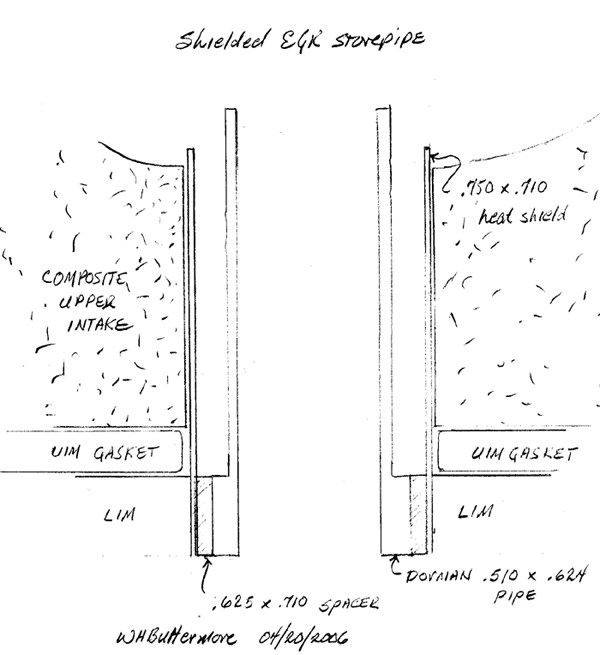

If you are going to buy a new Dorman upper that comes with a reduced diameter stovepipe (.510" pipe x .625" shoulder) , you could JB weld in a .750" OD x .035" wall sleeve without removing any plastic, and still have an .085" gap between pipe and sleeve. We can probably come up with an even thinner sleeve to give us .090" if we look around a bit. That fix can also be done for the 95-early 99s by cold pressing a ring onto the new Dorman pipe. I have done this and know that it works.

So, all we really need to go this route is the sleeve for the 99+ guys and the sleeve and ring for the 95-99s.

[edit: I found .750" OD x .020" wall 321 stainless steel (extra corrosion resistance) readily available for making sleeves. The ID of .710" would give a .100" air gap with the new Dorman pipe and require no plastic be removed from the new upper. Seems like a pretty good plan, just need to figure an easy method to keep the sleeve aligned nicely concentric in the bore while the epoxy sets up.]

This does not stop anyone from having you sleeve a used UIM as you have been for less money and a good fix if they can afford the time. Or from buying a sleeve and pipe or sleeve and ring and repairing their own.

If you are going to buy a new Dorman upper that comes with a reduced diameter stovepipe (.510" pipe x .625" shoulder) , you could JB weld in a .750" OD x .035" wall sleeve without removing any plastic, and still have an .085" gap between pipe and sleeve. We can probably come up with an even thinner sleeve to give us .090" if we look around a bit. That fix can also be done for the 95-early 99s by cold pressing a ring onto the new Dorman pipe. I have done this and know that it works.

So, all we really need to go this route is the sleeve for the 99+ guys and the sleeve and ring for the 95-99s.

[edit: I found .750" OD x .020" wall 321 stainless steel (extra corrosion resistance) readily available for making sleeves. The ID of .710" would give a .100" air gap with the new Dorman pipe and require no plastic be removed from the new upper. Seems like a pretty good plan, just need to figure an easy method to keep the sleeve aligned nicely concentric in the bore while the epoxy sets up.]

This does not stop anyone from having you sleeve a used UIM as you have been for less money and a good fix if they can afford the time. Or from buying a sleeve and pipe or sleeve and ring and repairing their own.

#2

Senior Member

True Car Nut

Thread Starter

Hey, here is some bitter justice for the 95-99 guys. If they are careful removing their stock .750 stovepipes, so they don't distort them, they can ultimately cut the old pipe up as a sleeve for the new Dorman upper after using it to drive their rd pipe down into the LIM bore.

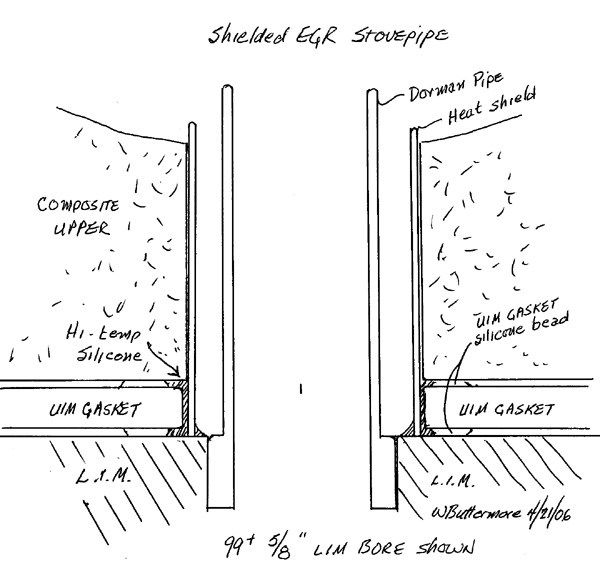

Yipes! This gives me another idea. We can make an insulating stovepipe with the Dorman as the inner and a thin .750 as the outer that would not have to be epoxied at all! Like the double and triple walled stovepipes for wood burning fireplaces.

So we attach the heat shield to the pipe, not the upper. OK, what'* wrong with this idea?

Drawing coming......

The spacer at the bottom and the heat shield would need to be a little higher up for the 99+, and we would want the spacer material to conduct heat so the LIM could still provide cooling, but the idea for the .625 LIM bore is basically the same.

If we go with a built-up pipe and shield it might be necessary to give up some of the gap to get a .035" outer wall that is strong enough to drive the unit into the hole - even so, that would leave us with .085".

Probably in production, in would not be that expensive to either CNC these from 6300 aluminum in one piece or fuse the bottom parts so the pipe could be easily installed without separating the parts as they are driven into the hole.

So, what have I overlooked here at 2 in the morning?

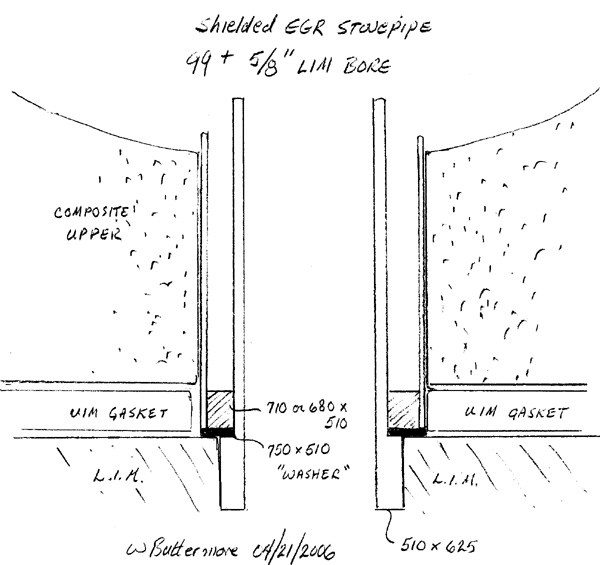

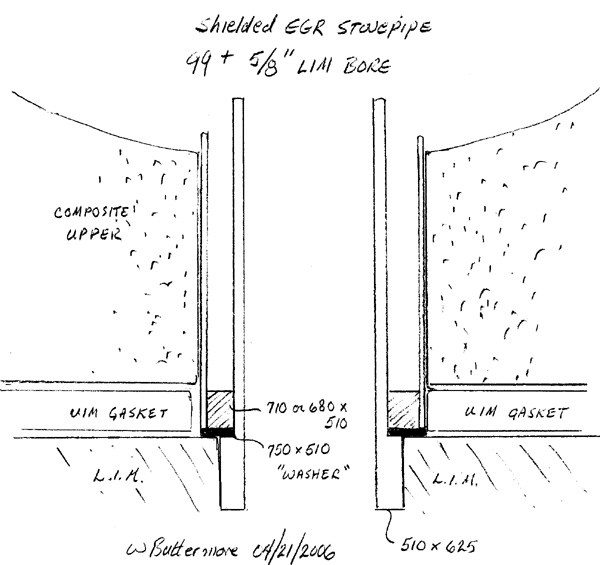

Here'* for the 99+. This works easier as a built-up for driving into the LIM bore.

This design will work for the earlier .750 bores by simply pressing the ring on the bottom that I have already tested.

3:30 AM ugh! must sleep.

[edit: It would be good to find an insulating material that could be used for the spacer (not the "washer") in the above image. In fact, if we could find a super insulator like they use for space shuttle tiles, it could be used to fill the gap instead of the oily carbon gunk that the engine will provide. But, as Bob Dillon pointed out to me, when the engine is running, the gap area is likely to exist as a partial vacuum, and a vacuum makes an excellent insulator. Just have to keep it open for the best results. Maybe check and clean the gap every 50,000 miles, like a spark plug....hmmm]

Yipes! This gives me another idea. We can make an insulating stovepipe with the Dorman as the inner and a thin .750 as the outer that would not have to be epoxied at all! Like the double and triple walled stovepipes for wood burning fireplaces.

So we attach the heat shield to the pipe, not the upper. OK, what'* wrong with this idea?

Drawing coming......

The spacer at the bottom and the heat shield would need to be a little higher up for the 99+, and we would want the spacer material to conduct heat so the LIM could still provide cooling, but the idea for the .625 LIM bore is basically the same.

If we go with a built-up pipe and shield it might be necessary to give up some of the gap to get a .035" outer wall that is strong enough to drive the unit into the hole - even so, that would leave us with .085".

Probably in production, in would not be that expensive to either CNC these from 6300 aluminum in one piece or fuse the bottom parts so the pipe could be easily installed without separating the parts as they are driven into the hole.

So, what have I overlooked here at 2 in the morning?

Here'* for the 99+. This works easier as a built-up for driving into the LIM bore.

This design will work for the earlier .750 bores by simply pressing the ring on the bottom that I have already tested.

3:30 AM ugh! must sleep.

[edit: It would be good to find an insulating material that could be used for the spacer (not the "washer") in the above image. In fact, if we could find a super insulator like they use for space shuttle tiles, it could be used to fill the gap instead of the oily carbon gunk that the engine will provide. But, as Bob Dillon pointed out to me, when the engine is running, the gap area is likely to exist as a partial vacuum, and a vacuum makes an excellent insulator. Just have to keep it open for the best results. Maybe check and clean the gap every 50,000 miles, like a spark plug....hmmm]

#5

Senior Member

True Car Nut

Thread Starter

While we are thinking out loud....How about just running a bead of high temperature silicone around the EGR bore hole of the UIM plastic gasket and letting the shield (sleeve) sit on the LIM with no spacer at all? Can't get that hot there, or we would have seen damage to the plastic gasket frame around the hole. Or use a slip fit spacer that requires no pressing or tools? Simple, cheap, easy. (Must be something wrong with an idea like that.)

I'll see if I can do another drawing.....

I'll see if I can do another drawing.....

#6

DINOSAURUS BOOSTUS

Expert Gearhead

I'd be leary about letting it sit there...even with some adhesive.

Highlanders first core arrived back with Bob just after the engine swap and Bob thought we sent him the sleeved one back. Highlanders stovepipe had come loose and lodged in the UIM>...looked just like a sleeved mani.

Highlanders first core arrived back with Bob just after the engine swap and Bob thought we sent him the sleeved one back. Highlanders stovepipe had come loose and lodged in the UIM>...looked just like a sleeved mani.

#7

Senior Member

True Car Nut

Thread Starter

Just tryin' to reduce the idea to its simplest expression. We have had really good luck with high temperature silicone adhesive/sealant on our steam locomotive in some really demanding applications.

I have heard of stovepipes that are really loose in the bore. A good reason to add a drop of loctite if you don't have a nice snug press fit. I'm guessing the pipe that got loose had no adhesive on it anywhere.

Anyway, here is the drawing for "the most simple" method of shielding the pipe.

Consider this - with a clean shield and a new upper, we could not only run a bead around the gasket hole, but smooth a layer all around the shield and even run a little fillet around the top of the pipe. Better for cooling to keep the fillet tiny or not there at all, though.

An apparent advantage to this technique would be that the shield also protects the UIM gasket and by touching the LIM on one end and the air stream (just a little bit, stealing from Bob Dillon'* concept here) on the other end, should pick up some conductive cooling on both ends. I like the idea of the shield sticking up just a little bit to catch the crud that accumulates around the hole and hopefully slowing the blockage of the air gap.

A benefit to using hi temperature silicone is that the shield and the silicone can be removed and the shield reused if needed.

I have heard of stovepipes that are really loose in the bore. A good reason to add a drop of loctite if you don't have a nice snug press fit. I'm guessing the pipe that got loose had no adhesive on it anywhere.

Anyway, here is the drawing for "the most simple" method of shielding the pipe.

Consider this - with a clean shield and a new upper, we could not only run a bead around the gasket hole, but smooth a layer all around the shield and even run a little fillet around the top of the pipe. Better for cooling to keep the fillet tiny or not there at all, though.

An apparent advantage to this technique would be that the shield also protects the UIM gasket and by touching the LIM on one end and the air stream (just a little bit, stealing from Bob Dillon'* concept here) on the other end, should pick up some conductive cooling on both ends. I like the idea of the shield sticking up just a little bit to catch the crud that accumulates around the hole and hopefully slowing the blockage of the air gap.

A benefit to using hi temperature silicone is that the shield and the silicone can be removed and the shield reused if needed.

#8

Senior Member

True Car Nut

Thread Starter

I ordered a length of .750" x .020 wall 321 stainless seamless tubing this morning to test the heat shield concept. I also placed a request in the "wanted" forum to buy a new Dorman pipe from some helpful BC member out there, so I can demonstrate how an everyday guy can press on a ring to make the little pipe fit in his 95-99 LIM.

Will return with update when I get the materials.

Will return with update when I get the materials.

#9

Senior Member

Posts like a Camaro

Bill,

Alignment could easily be maintained by turning down a piece of .750 aluminum bar stock to say .705 OD, drilling a .625 hole through the middle and then reaming it a few thous.

Say, 2" long. then, when the sleeve is installed and fitted to the LIM, it would slip inside the sleeve and center the stovepipe until the epoxy cured.

Same for the .510 stovepipe.

By the way, it'* easy to install your .750/.625 stovepipe. I slipped a 5/8" deepwell socket over the end and tapped it into place with a brass hammer. Worked perfectly.

Also, stovepies got here today-thanks!

Alignment could easily be maintained by turning down a piece of .750 aluminum bar stock to say .705 OD, drilling a .625 hole through the middle and then reaming it a few thous.

Say, 2" long. then, when the sleeve is installed and fitted to the LIM, it would slip inside the sleeve and center the stovepipe until the epoxy cured.

Same for the .510 stovepipe.

By the way, it'* easy to install your .750/.625 stovepipe. I slipped a 5/8" deepwell socket over the end and tapped it into place with a brass hammer. Worked perfectly.

Also, stovepies got here today-thanks!

#10

Senior Member

Posts like a Camaro

Another thought-if you're worrying about crushing the thinwall tubing installing a sleeve in new UIMs, it would also be easy to turn down a piece of aluminum bar stock to a few thous under the ID of the tubing, leave a flange on the end (it would look like a mushroom tappet valve lifter) and tap it in like that. With the internal support, the sleeve wouldn't crush.