%#$@$##@#%$*^%%^!!!!!!!!!!

#31

Senior Member

Posts like a Turbo

Originally Posted by willwren

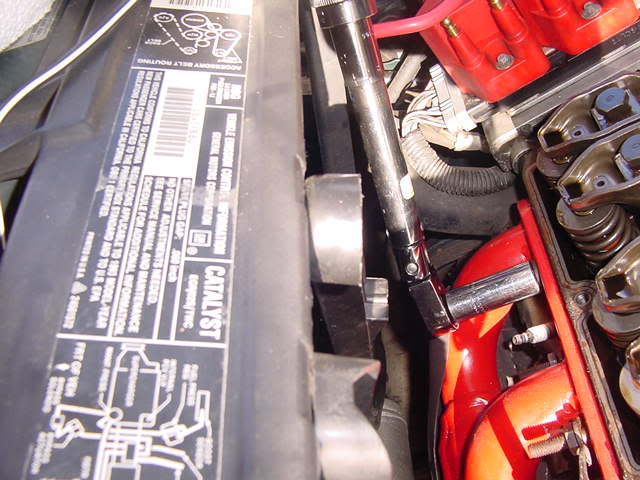

I just checked out a 3/8" drive swivel-head torque wrench from work. Swivels in only one axis, rather than 2 like a universal. That'll solve the problem.

#32

Senior Member

Posts like a Turbo

Originally Posted by Foghorn

Originally Posted by willwren

I'm trying to be anal about this, as I'm using gaskets on the re-install. Anyone got a clue?

Don't bother with the torque wrench, if you want to practice on another bolt and check with the torque wrench to compare tightness. Otherwise, use something like a 1/4" drive ratchet where you know it'* unlikely you'll over torque.

I use gaskets on mine and just used a 6" wrench to tighten...no leaks.

Don't do like I did this weekend though...I did the front passenger wheel bearing and broke a 3/8 to 1/2 adaptor getting it off and broke the TorX 55 on the last on the way in. Still, only took 1/2 an hour.

Cheers,

#33

Guest

Posts: n/a

Nick *, I think thats a great explanation.... Before I bought my 91 someone had removed the rear head from the engine... Not 100% sure what the reason ever was.... But they reused the Head bolts.... When I took them out I swear if that had been turned any further they would have snapped off in the block

Bill, I'm interested to see the progress you are making on the Zilla

__________________

Best Car Insurance | Auto Protection Today | FREE Trade-In Quote

Bill, I'm interested to see the progress you are making on the Zilla

__________________

Best Car Insurance | Auto Protection Today | FREE Trade-In Quote

#34

Don't bother with the torque wrench, if you want to practice on another bolt and check with the torque wrench to compare tightness. Otherwise, use something like a 1/4" drive ratchet where you know it'* unlikely you'll over torque.

I use gaskets on mine and just used a 6" wrench to tighten...no leaks.

I use gaskets on mine and just used a 6" wrench to tighten...no leaks.

#36

Senior Member

True Car Nut

Join Date: Apr 2004

Location: Three Oaks, Michigan

Posts: 4,879

Likes: 0

Received 0 Likes

on

0 Posts

nick: trust me, I know about the head bolts  .

.

I was thinking, if I were in Bill'* position, i'd torque all bolts the same [the way you get it the first time], then go back and make sure it'* still the same torque. To compensate for the header getting closer to the head. As far as bolt stretch.. IMO if the stretch varies so much between the bolts to the point where it will make the header not seal properly, and you are going to worry about it.. get new bolts.

I will agree about the bolts needing retorquing after a few heat cycles.. when I pulled my headers again they weren't very tight, but i torqued them down to 50ft lbs. Felt like around 30ft lbs.. maybe 40 at most.

-justin

.

. I was thinking, if I were in Bill'* position, i'd torque all bolts the same [the way you get it the first time], then go back and make sure it'* still the same torque. To compensate for the header getting closer to the head. As far as bolt stretch.. IMO if the stretch varies so much between the bolts to the point where it will make the header not seal properly, and you are going to worry about it.. get new bolts.

I will agree about the bolts needing retorquing after a few heat cycles.. when I pulled my headers again they weren't very tight, but i torqued them down to 50ft lbs. Felt like around 30ft lbs.. maybe 40 at most.

-justin

#38

Senior Member

Posts like a Turbo

Originally Posted by 2000SilverBullet

I know our gaskets are solid steel so should have no compressibility issues.

#39

Guest

Posts: n/a

Very nice piece of equipment.... Those always do come in handy... Progress looks good... Almost there are you?

__________________

Best Car Insurance | Auto Protection Today | FREE Trade-In Quote

__________________

Best Car Insurance | Auto Protection Today | FREE Trade-In Quote

#40

DINOSAURUS BOOSTUS

Expert Gearhead

The two ratchets in my collection that get used the most are the swivel heads. The are so universally great that they are the first I reach for.